Non Destructive Testing (NDT)

Authors: W.D. Dover, R. Collins, D. H. Michael

Ac-field measurement technique measures and interprets

field perturbations in a region containing a surface flaw.

ACPD, as it was originally called, has a long history of

malpractice but was so eminently suitable for laboratory

monitoring of fatigue cracks that it was reassessed for this

purpose. The technique consists of impressing an AC

current into the region containing the flaw and exploring

the surface—voltage distribution with a probe.

Initially edited in hard copy, this book was considered one

of the most relevant documents when published. Apart

from some new technologies that did not exist when it

was written, we can say that this document is still actual

and should be considered a reference.

Note that this is a big file, and downloading it takes time.

Authors: A.I.Bondarenko, E.O.Paton

Extended welded pipelines are characterized by the

presence of various discontinuities in them related to the

change of material density and/or cross-section of pipe

walls on their joint boundary and/or along the pipe

length. This paper deals with detecting these

discontinuities, with which low-frequency guided waves

of longitudinal and torsional modes interact during their

propagation in the form of a circular wave through the

pipe cross-section.

Author not indicated

Ultrasonic Testing (UT) uses high frequency sound energy

to conduct examinations and make measurements.

Ultrasonic inspection can be used for flaw

detection/evaluation, dimensional measurements, material

characterization, and more. To illustrate the general

inspection principle, a typical pulse/echo inspection

configuration as illustrated below will be used.

Author unknown

This presentation provides information on magnetic

particle inspection methods (MPI).

It can be used to teach divers on the purpose and

implementation of such procedures during mobilization

and maintenance. This document does not explain

underwater MPI.

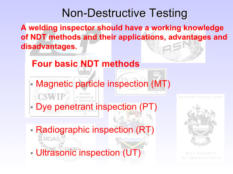

Publisher: Mark Stephen Rogers

This presentation shows the applications, advantages and

disadvantages of various Non-Destructive Techniques

(NDT) used in multiple industries, particularly in the

offshore and petroleum industries.

This document can be classified under the “Technical

document - Vessels” rubric. Nevertheless, it provides

guidelines that can be used to organize inspections.

Author:

Reza K. Amineh, Maryam Ravan, Hesamedin Sadeghi, and

Rouzbeh Moini

In the alternative current field measurement (ACFM)

technique, the nonzero value of liftoff distance for the

magnetic sensor acts as a low-pass filter on surface crack

signals, causing errors in crack detection and sizing. The

authors present a blind deconvolution algorithm for Liftoff

evaluation and surface crack signal restoration.

Publisher: Siemens Rolling Stock Pvt. Ltd, Aurangabad

This presentation can be used to inform personnel on

ultrasonic testing

Publisher: International Atomic Energy Agency

Even though this document is not specifically designed for

diving activities, it provides essential information regarding

Eddy Current.

Publisher: Dzevad Hadzihafizovic

This handbook provides basic information about weld

conditions, gauges, symbols, and weld terms.

Authors:

Jasper A. Agbakwuru, Ove T. Gudmestad, John Groenli,

Helge Skjaveland

This paper demonstrates a technique for tracking and

identifying leaking points on pipelines installed in

unclear/muddy water conditions using optical cameras.

The method leads a remotely operated or hyperbaric

system to the leak in muddy water conditions for close

visual inspection and subsequent repair.

Authors:

Ken Woolley, Tim Woolley, and Bruce Banfield

Since the beginning, underwater MPI has been carried by

night due to the inks' characteristics. New inks are now

available, although they are for topside use and thus are

not necessarily applicable to underwater conditions.

Recent trials have been conducted to determine the

suitability of available inks to increase white light levels

underwater. This paper presents the work and discusses

the findings, which have application worldwide.

Publisher: Frontline

This document provides procedures for visual and optical

inspection according to “Frontline”, a company specialised

in non destructive techniques

(https://frontlinetesting.com/ )

Authors: Restu Putra & Ahmad Irsyad

This presentation is another document that can be used to

initiate personnel to Eddy Current inspection.

Author: Mark W Hounslow

Particulate matter derived from various fuel combustion

sources contains minor to trace amounts of Fe-oxides that

magnetic measurements can detect. These magnetic

particulates can be used as proxies for particulate pollution

since oxide contents are often more significant in

quantities and may have distinctive magnetic properties

compared to most types of natural dust.

Author:

Ali Khaloo , David Lattanzi, Adam Jachimowicz, and

Charles Devaney

This paper presents a case study where photogrammetry

was used to create comprehensive and high-resolution

3D point clouds of a dam and surrounding environment

at intervals. These models were then assessed for their

quality and ability to resolve defects that were artificially

applied to the structure between inspection intervals. The

results indicate that the integrated process can generate

models that accurately render various defect types with

sub-millimeter accuracy.

Authors: Restu Putra & Ahmad Irsyad

This presentation is another document that can be used

to initiate personnel to Eddy Current inspection.

Publisher: International Atomic Energy Agency

Even though this document is not specifically designed for

diving activities, it provides essential information regarding

the use of NDT .

The organization for which it has been designed is proof

of quality.

This is another document from the International Atomic

Energy Agency, not specifically designed for diving

activities, that provides essential information regarding the

use of NDT.

Tomography is an x-ray technique in which shadows of

superimposed structures are blurred out by a moving x-ray

tube. This method is used in radiology, archaeology,

biology, atmospheric science, geophysics, oceanography,

plasma physics, materials science, astrophysics, quantum

information, and other areas of science.

This document is provided by the International Atomic

Energy Agency.

Click on the

octopus to return to

the top of the page

Authors: Duje Medak, Luka Posilovic, Marko Subasic,

Marko Budimir, Sven Loncari

Most ultrasonic data collection has recently become

automated, but the analysis of this data is still done

manually. This makes it expensive, inconsistent, and prone

to errors. An automated system could make processes

much more efficient, but the current methods are not

effective. Deep learning could be a more effective

approach for analyzing this data, as it has been successful

in similar cases. Based on this, the authors utilized a deep

learning model called EfficientDet to automatically detect

defects in ultrasonic images.

Authors: Chao Chen, and Xingyuan Zhang

A support vector machine-based method is proposed to

solve the challenge of accurately quantifying surface

defect depth during laser ultrasonic inspection. A finite

element model for laser ultrasound inspection of

aluminum materials with surface defects was developed

using COMSOL software, based on the thermal-elastic

mechanism.

Authors: Xiaofei Li, Heming Sun, Taiyi Song, Tian Zhang,

Qinghang Meng

This study focuses on the detection and identification of

structural cracks in underwater bridge structures using

advanced image recognition networks. It compares

different networks and outlines the methodology,

including ablation experiments to evaluate the

performance and accuracy of various network

combinations in identifying underwater structural

damage.

Authors: Sheng Shen, Zheng Cao, & Changqin Lai

This document describes the development of a sonar

scanning scheme designed explicitly for inspecting

underwater high-rise pile cap foundations (HRPCFs). The

goal is to enhance the efficiency of bridge inspections and

extend the structural durability of these foundations. It

discusses the experimental determination of critical factors

affecting sonar measurement accuracy, the design of a

platform to hold and move the sonar device under strong

currents, and the strategy for optimal placement of

measurement points to avoid signal obstruction.

Authors: Zehao Wang, Defeng Zheng, Xingsen Guo,

Zhongde Gu, Yueqiang Shen, & Tingkai Nian

This study explains the impact of submarine landslides on

underwater structures, focusing on bucket foundations. It

introduces a fluid-structure coupling system using the

coupled Smoothed Particle Hydrodynamics (SPH)-Finite

Element Method (FEM) to analyze the displacement

response of these foundations during landslide impacts.

The research aims to provide a new numerical simulation

approach and offers insights into underwater structures'

dynamic response and failure mechanisms under extreme

conditions.

Authors: Hao Wang, Kan Wang, Xiaolei Liu, Yang Liu,

Zhijia Qian, and Sheng Ding

This study explains the development and analysis of an

offshore floating photovoltaics (FPV)-based hydrogen

production system. It addresses the challenges, particularly

safety concerns, associated with hydrogen storage in such

systems. It involves creating a numerical 3D model to

investigate the characteristics of accidental damage and

hydrogen release under different offshore wind

conditions. It also explores the dynamic development of

hydrogen dispersion and evaluates the evolution of

thermal hazards and damage in the marine environment.

Publisher:

UK-HSE

This document is designed to guide plant engineers and

inspection personnel on methods for analyzing and

extrapolating inspections for large plant items, including

vessels, pipework, and pipelines, while considering the

statistical nature of corrosion. It aims to introduce methods

of statistical analysis of corrosion inspection data. Before

incorporating the methodology into standards, practical

experience in industrial applications is necessary to identify

the most relevant distributions and statistical techniques.

Publisher: UK HSEi

The document intends to inform the reader about the

importance of ultimate strength analysis in assessing the

robustness of offshore platforms and how this analysis can

be used to optimize inspection planning. It highlights the

role of EQE International, Inc. in conducting a study for

the Health and Safety Executive (HSE) to explore the

relationship between platform robustness and inspection

requirements.

This document describes the process and methodology of

the specific inspection project, Key Programme 3,

conducted by the HSE Offshore Division between 2004

and 2007. It explains how inspections were carried out,

the scoring system used (traffic lights), the roles of the

inspectors, and how the results were evaluated and

recorded, and provides an overview of the inspection

process, including the criteria for compliance and the

evaluation of safety-critical elements.

Author: Junfeng Fan, Yaming Ou, Xuan Li, Chao Zhou,

and Zengguang Hou

This document describes a new method for inspecting

underwater pipelines using underwater vehicles equipped

with structured light vision (SLV) technology. The text

outlines the limitations of current inspection methods and

introduces a proposed solution that involves a dual-line

laser SLV system. This system aims to improve precision,

resolution, and information capture for fine three-

dimensional reconstruction of underwater pipelines. The

text also highlights the integration of this technology with

the BlueROV underwater vehicle and presents

experimental results demonstrating the effectiveness of the

method.

Author: Hwei-Yang Tan

This study develops a new approach for analyzing

corrosion in the oil and gas industry, addressing limitations

in current industrial practices and standards by

incorporating statistical methods that account for various

risk factors and the stochastic nature of localized corrosion.

It improves the prediction of the remaining useful life of

components in oil and gas plants by utilizing advanced

statistical techniques and software.

Authors: Franka Nauer, and Peter Kampmann

This paper analyzes the current state and challenges of

autonomous underwater intervention technology,

particularly focusing on the use of intervention

Autonomous Underwater Vehicles (AUVs) for inspection

and maintenance of underwater infrastructure. It identifies

key requirements and challenges in the development of

high-level autonomy for these vehicles, such as decision-

making, tool handling, and precise navigation, and further

research and development in this field.

It can also be downloaded through this link:

https://webarchive.nationalarchives.gov.uk/ukgwa/20230

103120103/https://www.hse.gov.uk/research/otipdf/oti8

8539.pdf

Authors: Dr. John M. Webster. Dr Thanga Thevar. Tim

Schmidt. Jackie Mew

Corrosion in aluminium aircraft structures is a growing

issue in the aging fleet, which may affect safety. Existing

methods for detecting hidden corrosion are often slow

and not very accurate. Techniques like Thermal Wave

Imaging show promise, but challenges remain. Reliable

detection methods are still being developed, with early

results from Remote Acoustic Impact Doppler (RAID)

technology being presented.

3 - A New Computational Imaging Method for the Remote

Detection and Quantification of Hidden Corrosion

Authors: R. Raisutis, E. Jasituniene, R. Sliteris, A.

Vladisauskas

Wind power is a clean and renewable energy source

that requires regular inspection of wind turbine

components. This study reviews techniques for

monitoring and non-destructive testing (NDT) of wind

turbine blades, including vibration analysis,

thermography, X-ray imaging, acoustic emission, and

ultrasound. The goal is to assess various NDT methods

suitable for the complex structures of blades and harsh

conditions.

13 - The review of non-destructive testing techniques suitable for

inspection of the wind turbine blades

Authors: Peter W. Tse and J.M. Chen

The steel wire ropes used in elevators can rust and crack

due to exposure to salty air. Poor maintenance often

leads to accidents from broken wires. Current inspections

rely on human visual checks, which miss faults, especially

under grease. This study proposes an ultrasonic guided

wave technique for better detection of wire faults. Results

show that this method can find broken wires effectively,

even on greasy ropes, but needs further refinement for

on-site testing. Future research should focus on

improving operational parameters and developing

practical sensors.

20 - Effective Guided Wave Technique for Performing Non-

destructive Inspection on Steel Wire Ropes that Hoist Elevators

Authors: Oleg Gaidai, Yu Cao, Yan Zhu, Fuxi Zhang, and

Hongchen Li

A new reliability method suitable for multi-dimensional

structural dynamics is introduced in this study, using the

Gaidai multivariate method on an offshore Jacket

platform in Bohai Bay. It estimates collapse risks under

environmental stress, addressing challenges of high

dimensionality and nonlinear correlations. This method is

essential for offshore engineers during design to assess

operational failure, damage, or hazards.

36 - Multivariate Risk Assessment for Offshore Jacket Platformsby

Gaidai Reliability Method.

Authors: Jingzhou Xin, Guangjiong Tao, Qizhi Tang, Fei

Zou, Chenglong Xiang

This study proposes a new damage identification method

using Swin Transformer and continuous wavelet

transform (CWT). It converts structural vibration data into

a time-frequency diagram to capture damage

characteristics. The Swin Transformer extracts damage

information from this diagram. The method's accuracy is

analyzed with various sample lengths and noise levels,

confirming its robustness. Laboratory tests show it

recognizes damage with 99. 6% accuracy for single

damage and 99. 0% for multiple damages.

37 - Structural damage identification method based on Swin

Transformer and continuous wavelet transform.

Authors: Andrei Nazarov, Tatiana Yurasova, and Andrey

Marshakov

This review examines how different aqueous electrolytes

impact hydrogen absorption and self-corrosion in

magnesium anodes. It discusses historical and recent

studies on mechanisms of self-corrosion and hydrogen

evolution under specific effects. The focus is on

magnesium hydride formation and oxidation during

active dissolution and how anodic dissolution occurs

through protective films in other conditions. It also looks

at factors influencing hydride formation and self-

corrosion.

39 - Hydrogen Absorption and Self-Corrosion of Mg Anode:

Influence of Aqueous Electrolyte Species

Authors: Yuheng Chen, Haicheng Zhang, Weisheng

Zou, Haihua Zhang, Bin Zhou, Daolin Xu

This study proposes a new ROV-based deep-sea mining

system to address slippage and sinking issues of

traditional vehicles. A learning-based control strategy is

introduced, utilizing a nonparametric learning method to

improve path-tracking performance.

40 - Dynamic modeling and learning based path tracking control

for ROV-based deep-sea mining vehicle.

Authors: Beate Oswald-Tranta

Inductive thermography is a strong inspection method for

finding defects in metals. The technique has improved

over decades from lab tests to industry use. This paper

reviews its theory and key technical aspects. While it can

find various defects, the focus is on detecting surface

cracks in metals, with examples of current industrial

applications.

41 - Inductive thermography – review of a non-destructive

inspection technique for surface crack detection

Authors: Mohammadebrahim Bajgholi, Gilles Rousseau,

Denis Thibault, Simon Francoeur.

This study evaluates advanced Non-Destructive Testing

(NDT) techniques for detecting flaws in welded repairs of

martensitic stainless steel plates, focusing on Francis

turbine runners. Phased Array Ultrasonic Testing (PAUT),

Total Focusing Method (TFM), and Eddy Current Array

(ECA) technologies were examined to assess repair

integrity and identify flaws such as lack of fusion (LOF).

The findings highlight the necessity of integrating

advanced NDT techniques to ensure the structural

integrity of critical components, particularly in high-stress

applications such as turbine runners.

43 - Advanced Non-Destructive Testing Techniques for Welded

Joint Repairs: A Case Study on Improving Inspection Reliability

and Structural Integrity Assessment

Authors: Luca Paterlini, Andrea Marinelli, Andrea Brenna

and Marco Ormellese

This document proposes a risk map to manage

phenomena linked to the fact that carbon steel structures

that transport hydrocarbons have systems to prevent

corrosion, including cathodic protection and insulating

coatings, and that electrical interference, both AC and DC,

can cause corrosion even with protection applied.

44 - Protection Criteria of Cathodically Protected Pipelines Under AC

Interference.

45 - Natural van der Waals canalization lens for non-destructive

nanoelectronic circuit imaging and inspection

Authors: Qingdong Ou, Shuwen Xue, Weiliang Ma,

Jiong Yang, Guangyuan Si , Lu Liu, Gang

Zhong, Jingying Liu, Zongyuan Xie, Ying Xiao,

Kourosh Kalantar-Zadeh, Xiang Qi, Peining Li,

Zhigao Dai, Huanyang Chen, Qiaoliang Bao

Optical inspection is important in semiconductor wafer

manufacturing for analyzing surfaces and defects.

Traditional methods struggle with resolution and

detecting buried structures. The authors suggest a new

approach using a van der Waals canalization lens from a-

MoO 3 crystals, achieving 15 nm resolution for both

surface and buried imaging. This method offers better

imaging without the issues faced by other lenses,

enabling high-resolution inspection of buried nanoscale

circuits, crucial for future semiconductor manufacturing.

Authors: Andrzej Katunin, Krzysztof Dragan, Marko

Nagode, Krzysztof Lis, Kamil Joszko, Adam

Cholewa, Jernej Klemenc, Simon Oman, Paweł

Zak, Piotr Synaszko

Hidden corrosion, if not found quickly, can greatly

impact the strength and safety of aircraft. Enhancing

non-destructive testing (NDT) methods is crucial for safe

aircraft operation. The D-Sight technique is commonly

used for detecting this corrosion, valued in the

aerospace industry for its fast and low-cost inspections.

One of the drawbacks

46 - Towards quantification of hidden corrosion using D-Sight non

destructive testing technique

Authors:

Emmanuella Onyinye Nwulu, Tari Yvonne Elete,

Friday Emmanuel Adikwu, and Fidelis Othuke Onyeke

The durability of coatings is crucial for protecting

infrastructure from damage. This study suggests a

framework using advanced non-destructive testing

(NDT) technologies for inspecting coating durability. It

incorporates methods like ultrasonic testing and data

analytics to find defects and predict lifespan. Case studies

show this approach improves decision-making and saves

costs. The framework promotes better inspection

practices across different sectors for enhanced

performance and sustainability.

42 - Advancing inspection techniques for coating durability: A

framework for integrating non-destructive testing technologies.