Road-transportable modular pontoons

Diving and ROV operations requiring surface-supplied or saturation

diving systems and work-class ROVs, along with tools such as cranes,

excavators, and pipe or cable laying systems (see photos below), as

well as other heavy equipment, need surface support offering ample

space. These operations sometimes occur in areas like rivers, natural

lakes, artificial lakes with dams, congested port sections, or island

lagoons isolated from the open sea by very shallow reefs, which are

inaccessible to typical diving support vessels and barges used at sea.

In such cases, road-transportable modular pontoons, which consist of

floating platform sections designed for easy transport on standard

trucks and assembly on-site into large floating structures, can provide

an ideal solution.

It must also be considered that such pontoons can be used to create

temporary jetties when operating in rivers or lakes with banks too

shallow to allow small boats to approach, forcing personnel to jump into

the water to embark and disembark, and preventing the transfer of

large equipment.

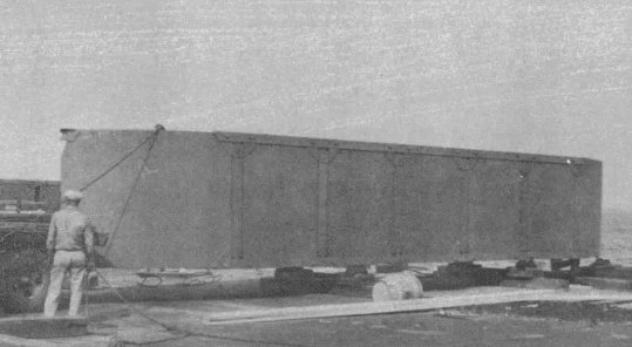

Regarding the historical origin of these technologies, it is worth noting

that while the use of floating bridges dates back to antiquity, and

perhaps earlier, the concept of using modular floating jetties to create

entire port facilities dates back to World War II, when the British

engineered and deployed temporary, portable harbors known as

"Mulberry Harbours" for the D-Day landings on the Normandy coast

(France) in June 1944 (see the picture below).

Current road-transportable modular pontoons, convenient for

organizing diving and ROV operations in the aforementioned areas, can

be made of steel and high-density polyethylene (plastic). Note that

while anodized aluminum is still used in the construction of floats for

some marina pontoons and small barges, it appears that this material

is no longer employed in the design of road-transportable modular

pontoons, except for frames supporting additional floors.

Modular steel pontoons are typically composed of rectangular modules

that are often compartmentalized into several sections. These

compartments are frequently left empty, which allows for regular

verification of their integrity. In some cases, they may be filled with

closed-cell foam to reduce the risk of flooding in case of punctures or

leaks. However, this advantage results in the inconvenience that the

integrity of compartments cannot be visually checked from inside. The

decision to leave compartments empty or fill them with foam depends

on several factors, including the manufacturer's design, the intended

use of the pontoon, and specific client requirements.

These pontoons are provided with clamping systems allowing them to

be assembled in various configurations to create large surface

supports. These configurations can be customized to surround

structures or be simple shapes like squares or rectangles.

These clamping systems are usually specific to each manufacturer, so

merging pontoons from two different manufacturers is not ordinarily

possible. We can see these differences in the modules below from

Poseidon Barge (https://www.poseidonbarge.com) and ETC Marine

(https://www.ectmarine.com).

The smaller modules are typically about 4 m (L) × 2 m (W) × 0.7 m

(H), weigh between 1.2 and 2 tonnes, and have a load capacity of up to

10,000 kg/m², depending on the unit.

The larger modules can typically be up to approximately 12 m (L) × 3

m (W) × 1.5 m (H), weigh around 11 tonnes, and have a load capacity

of up to 10,000 kg/m².

Barges designed with such modular pontoons can be anchored in

various water bodies such as lakes, rivers, or ports using anchors or

legs, depending on the operational depth.

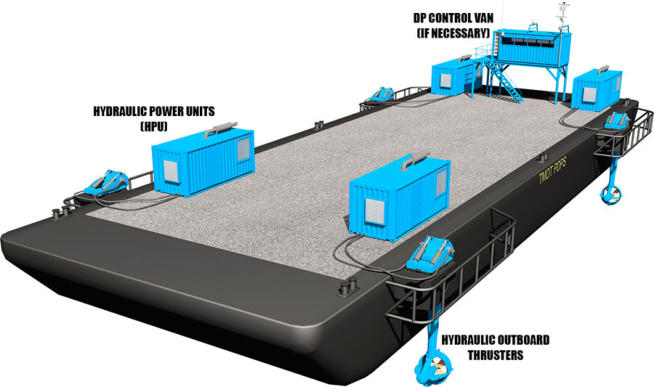

They can also be equipped with portable thrusters and dynamic

positioning (DP) systems, allowing self-propulsion and positioning, such

as illustrated below by Thrustmaster (https://www.thrustmaster.net), a

well-known manufacturer of such equipment.

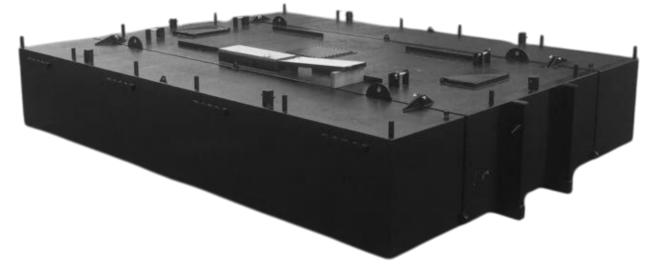

The concept of modular steel pontoon sections, which could be

transported by truck and assembled into barges, ferries, or floating

docks, dates back to at least the World War II era (1940s) and

possibly earlier within military engineering circles. (Click on the photo

below that shows such a unit to open the 1942 installation manual.)

These military-style modular pontoon units were then adapted into

commercial barge platforms for the civil engineering, salvage, and

dredging industries following the 2nd World War. In parallel, the

concept of floating jetties has been widely reused to organize port

facilities for small recreational boats and sometimes large vessels at

more favorable costs than classical piers. However, please note that

even though they can be considered an example of the use of this

technology, the floating jetties used to create “Mulberry Harbours”

could not have been transported by road due to their size. Therefore,

this article focuses only on light units that can be carried by “normal”

trucks, so as not to necessitate the organization of an exceptional

convoy for their transfer, and that can be easily installed using a light

crane. It must be considered that due to their size, exceptional convoys

may not access difficult-to-reach areas.

Also, note that some manufacturers claim that barges assembled with

their modular steel pontoon sections can be used in open sea

conditions. Regarding this point, I recall participating in the repair of an

optical fiber cable between Dover (UK) and Calais (France), diving from

such a barge, and completing the operations on time despite several

days of rough weather.

Providing the address of every manufacturer of this type of

equipment would be a very long and nearly impossible task,

considering that small shipyards produce them alongside established

manufacturers. However, the directory below lists some well-known

brands of such equipment designers, whose websites offer

information to better understand their products:

•

Damen:

Damen Shipyards Group - Pontoon Division - P.O. Box 1 - 8260 AA

Kampen, The Netherlands

Website: https://www.damen.com/vessels/pontoons-and-barges/

modular-pontoons

Email: info@damen.com

Phone: +31 (0)38 385 8585

•

ECTMarine:

Unit 4, The Mill Industrial Estate, Mill Road, Fareham, Hampshire

PO16 0TH, United Kingdom

Website: https://www.ectmarine.com

Email: sales@ectmarine.com

Phone: +44 (0)1329 288 121

•

Aqua Dock:

Hereford House, Bath Parade, Cheltenham, Gloucestershire, GL53

7HU, United Kingdom

Website: https://www.aqua-dock.co.uk

Email: sales@aqua-dock.co.uk

Phone: +44 (0)1242 216820

•

Flexifloat Systems

PDM Bridge, LLC (Flexifloat) 1000 PDM Way - Point Pleasant, WV

25550, USA

Website: https://www.flexifloat.com

Email: info@flexifloat.com or sales@flexifloat.com

Phone: +1 (304) 675-2361

•

Modular Pontoon Systems (MPS B.V.)

Nijverheidsweg 12, 3641 RP Mijdrecht, Netherlands

Website: https://mpsbv.com/

Email: info@mpsbv.com

Phone: +31 (0)418 – 67 80 86

•

Poseidon Barge

5000 Hwy 308 (River Road) Belle Chasse, LA 70037, USA

Website: https://www.poseidonbarge.com

Email: info@poseidonbarge.com

Phone: +1 (504) 656-9800

•

Weifang Dragon Machinery Technology

No. 1688, Yuhe Road, Weifang City, Shandong Province, China 261000

Website: https://dragonsolution.en.made-in-china.com/

Email: sales@dragonfloat.com

Phone: +86 536-227 2889

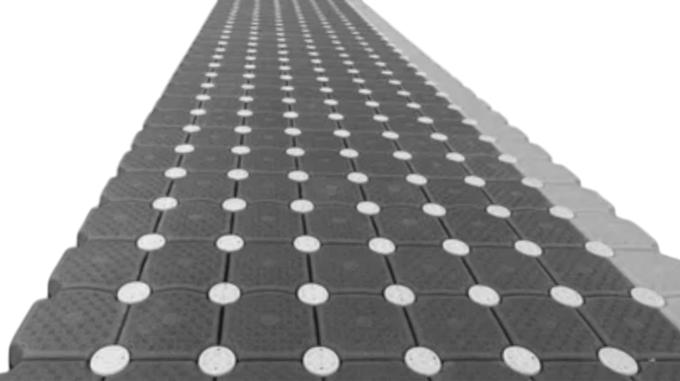

HDPE (High-Density Polyethylene) pontoons with UV stabilizers are

popular due to their resistance to corrosion, ultraviolet rays, and

impacts, providing good durability, low maintenance, and lifespans

exceeding 15 years.

They typically consist of square molded modules, each measuring

about 0.5 m on each side and 0.4 m in height, joined using dedicated

corner connectors or pin-and-nut systems."

Installing them is straightforward and usually requires no specialized

staff or heavy equipment, as the modules (weighing around 7 to 10 kg)

can be hand-carried and transported in small vehicles over rough or

unprepared roads.

They are widely used for floating working platforms and jetties

deployable on natural or unprepared shorelines.

Their load capacity is generally around 350 kg/m², with some

systems designed to support up to 750 kg/m² when configured in

double layers. They are therefore unsuitable for heavy loads, although

many suppliers offer steel or aluminum subframes and flooring to

distribute weight more evenly.

Similar to steel modular pontoons, there are many manufacturers of

HDPE (High-Density Polyethylene) pontoons with UV stabilizers.

However, the market is highly fragmented, with companies frequently

appearing or disappearing, making it impractical to maintain a

complete and current list. Many of these manufacturers focus

exclusively on the marina and leisure market, and although their

products could technically be adapted for mobile work units, their legal

acceptance for such use is uncertain. To avoid recommending

potentially non-compliant products, I have limited my selection to

manufacturers who explicitly describe this application in their product

specifications.

•

National Pontoon Ltd:

Unit 4, Mill Lane Industrial Estate, Wimborne, Dorset BH21 2JW,

United Kingdom

Website: https://www.nationalpontoon.co.uk

Email: sales@nationalpontoon.co.uk

Phone: +44 (0)1202 849400

•

Pontoonworks Ltd:

Unit 4, Mill Lane Industrial Estate, Mill Lane, Wimborne, Dorset BH21

2JW, UK

Website: https://www.pontoonworks.co.uk

Email: sales@pontoonworks.co.uk

Phone: +44 (0)1202 849400

It must be taken into account that a few manufacturers offer large-

dimension high-density polyethylene (HDPE) modules. One example is

Perebo, a company headquartered in Germany that provides units with

the following typical dimensions: 5 m (L) x 2.5 m (W) x 1.2 m (H). These

modules are assembled similarly to steel models and can withstand a

load capacity of up to approximately 400 kg/m². The weight of these

units is not mentioned.

•

Perebo contact:

Industriestraße 1 49439 Steinfeld, Germany

Website: https://www.perebo.com

Email: info@perebo.com

Phone: +49 (0) 5492 980-0

Note that HDPE (High-Density Polyethylene) pontoons are also used as

floating supports for activities such as fish farms and solar farms as

a result of their reasonable costs and ease of transportation,

installation, and maintenance.