About the power and data cables and

connectors of the diving umbilicals

The article "Will Bio-Inspired Underwater Vehicles With Artificial

Intelligence Replace Divers?", published in May 2024 in the Food for

Thought section of this website, argues that rather than replacing

divers with machines equipped with artificial intelligence, the

appropriate policy would be to enable them to work in symbiosis with

these machines. As a result, commercial diving companies need to

find or develop the necessary tools to achieve that capability. For this

reason, implementing diver monitoring systems, such as those

previously described in a dedicated article in this section, in addition to

SONAR and heads-up displays in divers' helmets, appears to be an

essential approach many commercial divers have long envisaged.

Therefore, it is pleasing to learn that the US Navy shares a similar

approach and that the company Coda Octopus, headquartered at 3300

S Hiawassee Road #104-105 Orlando, USA, has developed for them

the "Diver Augmented Vision Display System (DAVD)", which is now

available to commercial diving companies.

However, the installation of such a system, which provides the diver

with sonar images, graphics, navigation maps, and augmented and

virtual reality, in addition to the camera, sonar images, hot water

temperature (when used), and other information that needs to be sent

to the diving supervisor, requires a suitable power and data

transmission system compact enough to allow easy handling and

designed to avoid interference, so the diver and diving supervisor are

provided with untainted information at all times during the dive.

That opens a discussion on the evolution of data transmission cables

and connectors and why choosing some systems over others is

appropriate when purchasing new umbilicals.

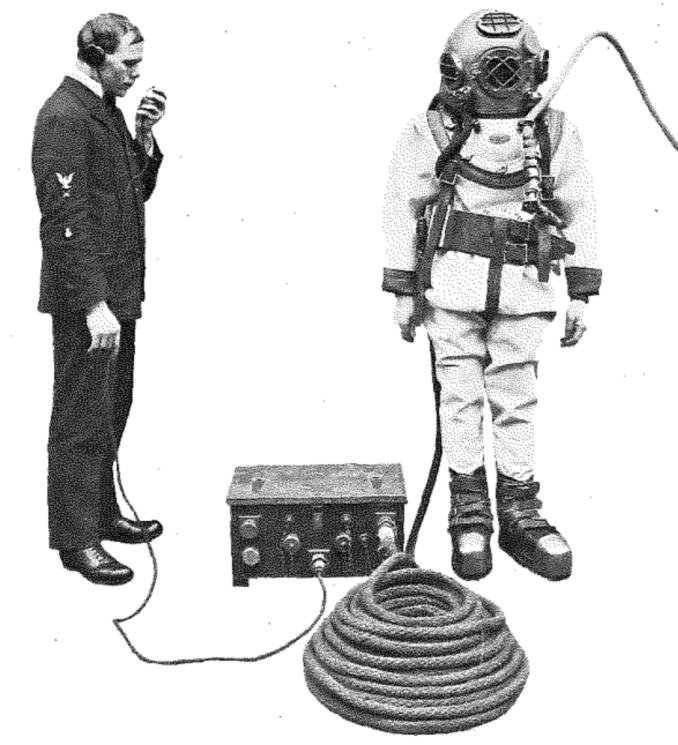

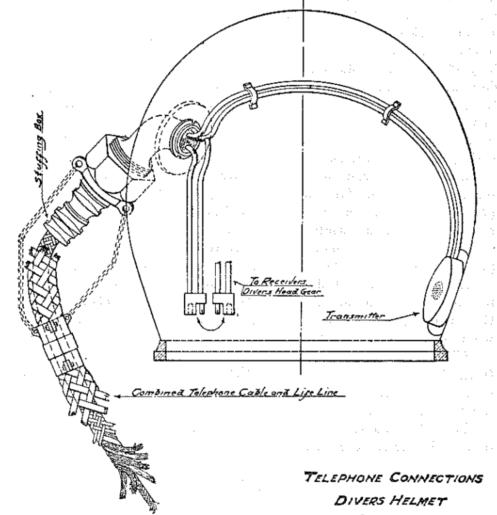

The problems associated with providing voice communication and light

to divers at work have been persistent since the early days when

these essential tools were first adopted and installed. For example, the

pictures below, taken from the 1924 US Navy Manual, which is available

along with others in the "Historical Diving" subsection of the

"Documents" section, illustrate how communications were designed

100 years ago.

Air supply

Life line + telephone

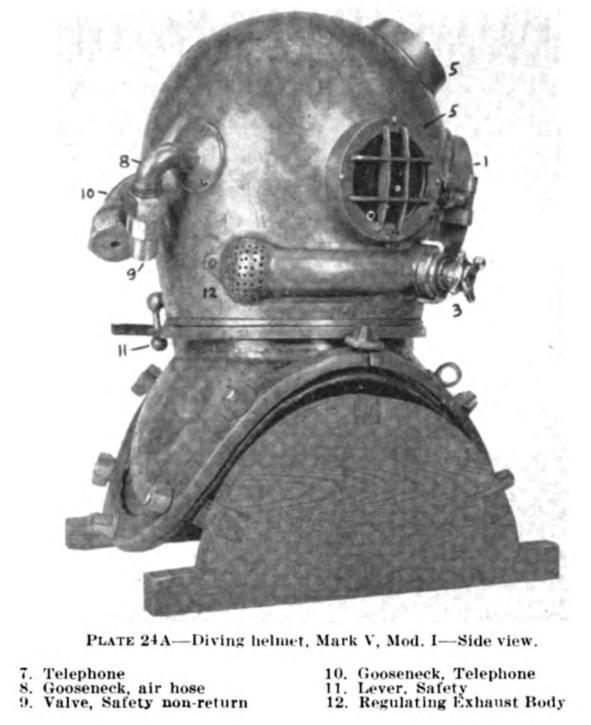

The telephone cable was integrated into the lifeline. The electrical

conductors formed the core of the assembly, with the rest of the

structure acting as a lifeline and protection for the conductors. The

telephone cable connection was positioned at the back of the helmet

(see #10 below), and the assembly cable/lifeline was curved to pass

under the diver's arm (see picture above) and be secured on the top

part of the harness or to the helmet, thereby providing sufficient

flexibility for the telephone cable not to pull on the connection directly.

Note that the lifeline was separate from the rubber air hose, which

was not used to pull the diver as it was not strong enough for that

purpose.

It should be noted that underwater lights during the 1920s were not

mounted on divers' copper helmets. Instead, they were separate units,

typically powered by 6 or 12 volts of direct current (DC). Divers would

install these lights in their immediate proximity to effectively illuminate

their working area.

In the 1970s and 1980s, the development of the offshore diving

industry led to a new generation of helmets made from composite

materials and equipped with lights and cameras. These advances

provided divers with greater safety and freedom (lead shoes were

replaced by fins or rubber boots, and helmets became lighter and

more neutrally buoyant) and allowed the dive supervisor to better

monitor and assist the diver.

This led to the addition of two cables to the communications cable,

which were secured with the lifeline along the air (or heliox) hose (see

below). The disadvantage of such a design is that the diver's umbilical

can easily become entangled when diving in cluttered areas, such as

inside platforms or wrecks, as the cables and lifeline are seldom held

perfectly along the air hose, resulting in loops that various objects can

easily catch. In addition, the additional cables reduce the flexibility and

weigh down such umbilicals, increasing their diameter and making

them more prone to being dragged along by underwater currents.

Blue: Air hose Yellow: Pneumo hose

Red: Communication cable Orange: Video cable

Grey: Light supply cable White: Life line

The reason for using separate cables was that, while DC power is not

inherently a source of interference, the potential for electromagnetic

interference (EMI) and crosstalk increases when power and signal

cables are close together. This can degrade the quality of video and

communication signals. Proper cable management and shielding

techniques, which were unavailable then, should be used to mitigate

these risks. Consequently, with the technology available, it was

generally advisable to avoid grouping DC power cables with video and

communication signal cables.

The picture below, taken from the US Navy Manual Revision 6, shows

that such umbilicals were still used by the US Navy in 2008.

Additionally, note that some equipment suppliers still sell them.

Considering that the previously discussed "Diver Monitoring Systems"

are useful tools some clients and states request to be in place or may

require in the near future, in addition to the advantages offered by the

Diver Augmented Vision Display System (DAVD), which should be added

to the Diver Monitoring System, as mentioned in the article "Will Bio-

Inspired Underwater Vehicles With Artificial Intelligence Replace

Divers? ", published in May 2024 in the Food for Thought section of

this website, the best choice is to adopt a cable grouping power

supplies and data transfer when purchasing a new umbilical, even if

some of the connections it provides are not intended to be used at the

time of the transaction. Additionally, while it is acceptable for

conservative individuals to purchase modern umbilicals with the

previous two-cable design, old-designed umbilicals, which have their

lifeline and cables kept along the rubber air hose using tapes, should

be definitively banned for the reasons previously explained.

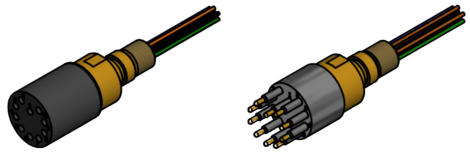

Also, as suggested above, connectors are essential parts of the power

supply and data transfer line as they should be fully waterproof, not

prone to disconnection, and allow for the perfect isolation of each

connection. In this regard, reports on the Coda Octopus Diver

Augmented Vision Display System (DAVD) indicate that it uses a

connector from the "micro-circular series" developed by SubConn

(https://www.macartney.com/connectivity/subconn/), which allows

signals and power supplies to be combined in a single connector and

secured by a “locking sleeve”, as shown in the drawing below

illustrating this series.

It should be noted that two types of communication links were and are

still used:

•

Four-wire communication cables allow the installation

of duplex communications, enabling all

parties connected to the system to talk

and listen simultaneously. They were

preferably connected by mash marine-types

connectors for an extended period. However, many umbilical

manufacturers today prefer connectors equipped with a “locking

sleeve” that prevents accidental disconnection.

•

Two-wire communication cables do not provide the advantages of

the four-wire system, as the diver and the supervisor use the

same line to send and receive messages. They were, and still are,

often connected to the helmet via two

specific screws secured on the shell.

Although the main advantage of this

design is its simplicity, it exposes the

wires to water that climbs along them

by capillarity, resulting in corrosion and

the need to cut the extremity of the cable periodically.

For this reason, waterproof connectors should be preferred.

.

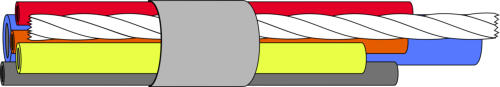

The development of the diving and ROV industries has resulted in a

new generation of umbilicals being offered to divers since the late

eighties, with the establishment of well-known companies such as

Cortland Fibron and Umbilicals International. This new generation of

umbilicals is typically constructed from a combination of more robust

and durable materials than the rubber previously used. The primary

materials include high-strength synthetic fibers such as Kevlar or

Aramid, which provide excellent tensile strength and abrasion

resistance. The outer sheath is often made from polyurethane or other

tough polymers to provide protection against physical damage and

environmental factors.

As a result, they are strong enough to support the diver's weight,

eliminating the need for a safety line, and the depth gauge hose and

various cables have been twisted along the main gas hose in the

manufacturing plant to form a single piece, eliminating the need for

taping. Technical advances have also made it possible to combine the

communication and video wires into the same cable. However, the

power supply for the light remains separate, resulting in two cables

installed along the air supply hose (if the umbilical is designed to

supply a helmet light).

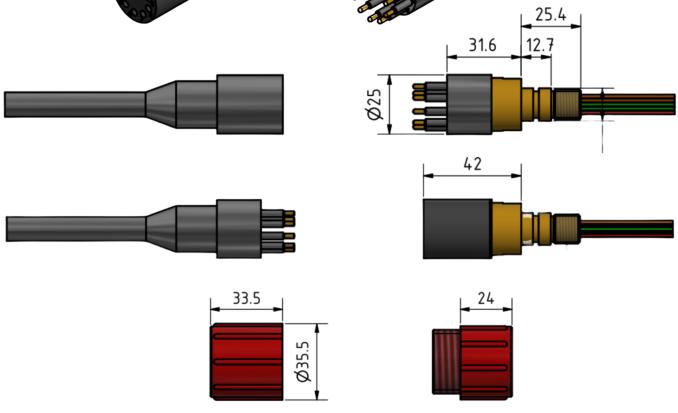

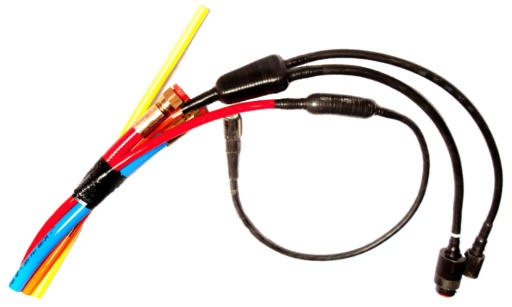

The grouping of wires with several functions in the same cable

requires the installation of a "pigtail", where the different wires are

bundled together to supply the devices to which they are dedicated.

Extensions with connectors, preferably models with a locking sleeve to

keep them in place, are installed to connect the camera and

communications (see figure below). The pigtail construction process

uses special rubber compounds designed to withstand harsh

underwater conditions. The construction process involves pouring the

rubber into moulds to form the desired shapes, which are then cured

to achieve the required strength and flexibility. Kits are sold to create

custom moulded components on site when the original pigtail needs to

be replaced.

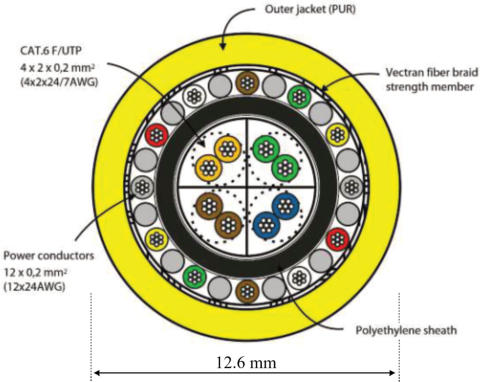

This type of umbilical is sold by many manufacturers, such as Divex

(https://www.jfdglobal.com/products/commercial-divers-

equipment/surface-supply/divex-diver-umbilicals/). However, a more

advanced design of cables is now available from some manufacturers

that combine all the power and data wires into one cable.

Manufacturers such as Novasub, a company based in the Netherlands

(https://www.novasub.com/product-categorie/cables-umbilicals/),

offer these advanced designs, with some cables offering up to 20

wires. These are, of course, the cables suitable for systems such as

the Diver Augmented Vision Display System (DAVD), which require a mix

of data and power cables, and the diver monitoring systems that are

today mandatory in some countries such as Norway and with some

clients. The section below of the Novasub DLR-CAT6-12C24 shows that

the 20 cores are contained in a cable with a diameter of 12.6 mm,

which is consistent for installation on a diver's umbilical.

Please note that SubConn is an American brand under the MacArtney

Group (https://www.macartney.com/), a Danish company specializing in

underwater technology solutions, which is listed with many other

manufacturers on our website in the "Power and Data Connectors and

Cables" subsection of the "Diving Equipment Manufacturers &

Suppliers" section within the "Logistics" main section. This sub-section

can be accessed by clicking on the button below.

Note: the dimensions are in mm

Click on the

octopus to return to

the top of the page