Diving into nuclear power plants is specific to only a few companies

rigorously selected by the operators. For this reason and to ensure

relevant information, I have contacted Patrick Lucon, the diving

manager of “Onet Technologies CN”, a company specializing in these

activities, headquartered in Marseille, France. who provided me with

a presentation I have adapted for this article. Note that in addition to

services to the nuclear industry, this group, which operates

worldwide, is specialized in the design and production of specific

communication systems, asbestos removal, waste management

services, and many other activities.

The diving department of “Onet Technologies CN” was initially

“COMEX Nucleaire”, a company created in 1990 by the COMEX group

that was bought in 1999 by “Onet Technologies CN”.

The need to work and dismantle installations in contaminated

nuclear pools created this diving activity that initially employed

divers who previously worked on military experimentation sites.

SOGETRAM, a subsidiary of the COMEX group that specialized in

interventions in unhealthy surroundings in addition to onshore and

inland diving operations, was one the 1st company involved with this

market in France before the creation of “COMEX Nucleaire” (Note that

SOGETRAM no longer exists).

The company operates for clients such as EDF (1), ORANO (2), and

CEA (3), and all types of diving work are done in their nuclear

facilities (mechanical, inspection, welding, etc.). These interventions

can be anticipated or incidental, requiring continuous personnel and

material availability.

Nuclear diving is an activity in a radioactive environment, and no

school trains divers for it. For this reason, Onet Technologies CN

trains its divers in specific gestures and procedures to allow them

to work in the very closed nuclear industry environment safely.

Trainings are regularly carried out in the COMEX swimming pool in

Marseille, France, or in pools similar to those of the nuclear facilities

in service at the "Centre d'expérimentation des techniques

d'intervention sur les chaudières nucléaires" (Experimentation

centre for technical interventions on nuclear boilers), also know

under the acronym "CETIC". This makes it possible to carry out the

most appropriate gesture for saving time and limiting the ionising

radiation dose absorbed by the diver during his exposure time

(measured by dosimetry).

The study and manufacture of suitable equipment are necessary.

For this reason, a close collaboration is established with the Onet

Technologies design office and the well-known nuclear power plants

manufacturer "Framatome" (4). Also, based on the 30 years of

experience acquired by the company, the diving department

continuously improves the diving systems, which are standardized

as follows:

•

Fully sealed reinforced rubber dry suits, like those made by

"Viking" or "Gates", equipped with waterproof rubber gloves, so

that no part of the body is exposed to the water, are the only

type of suits used currently. Note that for ionising radiation

exposure reasons, the diving team uses only one suit, which

result that the divers of a team should be of similar

mensuration to be able to use this suit safely.

•

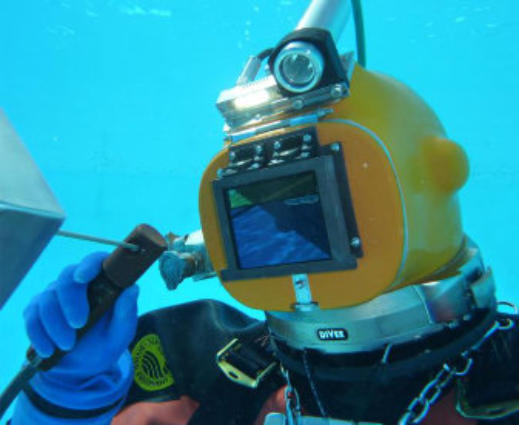

The helmets used are continuous flow types. The company has

successfully used the Aquadyne AH3 and AH4 in the past, and

now the AH5, which is the latest evolution of this helmet

(Aquadyne is a Brand of JFD). However, the exhaust valve of

these helmets has been modified as the original model did not

allow working in any position without water intrusion: As a

reminder, this adjustable exhaust valve is provided with a "Head

button" that can be operated by a movement of the head for the

accelerated evacuation of the air contained in the suit, allowing

the diver to quickly adjust his buoyancy and avoid an

uncontrolled ascent (blow-up). As water intrusions were

noticeable when the diver operated this button in the laid

position, and because a perfect sealing is essential, this exhaust

valve had to be modified. This problem has been solved with

the help of COMEX Pro diving systems designers and then

those of COMEX Nucléaire.

In addition to the above, the company has closely worked with

Beat Engel (Composite - Beat Engel) on designing a new helmet

better adapted to its nuclear diving activities. This project,

started five years ago, results in a new model equipped with a

removable weight that allows additional comfort during the

diver's long dressing and undressing phases. These long

phases are linked to the fact that the diver must be fully

assisted during the dressing phase, as he must never touch the

outside of the suit for obvious contamination reasons. It is the

same for the undressing phase, where in addition, a thorough

decontamination must be done by the assistants to guarantee

an undressing without risk before being allowed to get out of the

suit. As the helmets are calculated to have a neutral buoyancy,

they are quite heavy outside the water. For this reason, a helmet

with a removable weight has been considered an advantage

regarding comfort and, thus, fatigue of the diver.

Specific and strict operational procedures must be in place:

A radiation dosimetry must be conducted to identify and quantify

the nature and impact of the radiological risks to which the divers

will be exposed before starting the diving campaign.

A map identifying the radiation context is established under the

responsibility of the Radiation Protection Department of the site:

•

A first mapping is carried out from the surface before any

diving campaign. absorbed in real time. This makes it possible

to better manage the traveling and gestures of the diver.

•

In function of the cartography, more precise measurements

are carried out at the start of the dive in areas inaccessible

from the surface.

•

The volumetric activity of the water and the nature of the

radioelements* are also requested. (*Radioelements = Element

that are radioactive). For information, underwater, the

radiological dose rate decreases by a factor of 2 when moving

away from 10 cm. This is why nuclear diving is considered

suitable.

Another point to take into account is that the water of nuclear pools

is often hot (consider temperatures between 24 and 34 °C). For

safety reasons (hyperthermia), the company considers that the

water temperature for diving intervention should be below 28 °C.

Depending on the intervention criteria, a specific study by the

hyperbaric doctor and the company's hyperbaric prevention advisor

can be considered.

The composition of a diving team is 5 people, organized as follows:

- 1 diving supervisor

- 1 working diver

- 1 standby diver

- 2 divers operating as tenders

Therefore, the functions of the team members are identical to those

in force in the offshore industry, with a diving supervisor managing

the dive and a standby diver ready to intervene as quickly as

possible in an organized manner on the supervisor's instruction in

case of an incident or accident. For this reason, the standby diver is

not involved in any other activity than waiting for the instruction to

rescue the diver at work, and is partially equipped, as it is the case

in the offshore industry.

In addition to the precautions already mentioned, the intervention of

the diver is organized to manage and minimize the radiological risks:

•

The diver’s suit is provided with several radiological probes

(one on each foot, one on each wrist, one at chest level, and one

in the back), allowing the diving supervisor to know the

radioactive dose absorbed in real time. This makes it possible to

better manage the traveling and gestures of the diver.

•

The diver moves along a path previously defined in the work

procedure according to the radiological mapping of the

environment.

•

A precise radiological survey is carried out in the intervention

area, and the diver is equipped with a radiological probe for this

reason. This submerged probe must remain available and close

to the diver throughout the intervention.

Nuclear diving remains a particular activity where errors are not

allowed. For this reason, in addition to the working methodology and

intervention procedures mentioned above, the mentality of the

divers contributes to working safely in this very closed field of

activity.

Notes:

1.

Orano SA is a multinational company headquartered in

Châtillon, France, specializing in uranium mining, conversion,

and recycling. The company also provides logistical,

engineering, and intervention services to the nuclear industry.

2.

EDF is the acronym of “Electricite De France” (Electricity of

France), a French multinational electricity producer mainly

owned by the French state and headquartered in Paris, France.

The company operates various types of power plants

worldwide and is one of the major operators of nuclear power

plants.

3.

CEA stands for “Commissariat a l'energie atomique” (Atomic

Energy Commission). As suggested by its name, it is a French

public research organization initially specialized in the civil and

defense nuclear industry whose function is to create

synergies between fundamental research and advanced

technology, including designing nuclear reactors and

manufacturing specific systems. For a few years, the mission

of the commission has been extended to the study of other

energies, resulting that its name is now changed to

“Commissariat a l'energie atomique et aux energies

alternatives” (Alternative Energies and Atomic Energy

Commission), without changing the acronym under which it is

known.

4.

Framatome is a nuclear systems and power plants

manufacturer operating worldwide and headquartered in

Paris, France.

Contact:

Patrick Lucon: LuconP@onet.fr

Complemetary paper:

The document “Diving protection against nuclear contaminants”,

published in 2020 by Nicusor Chiripici, Amil Avram, & Laurentiu

Mocanu can be read in the section “Diving equipment”

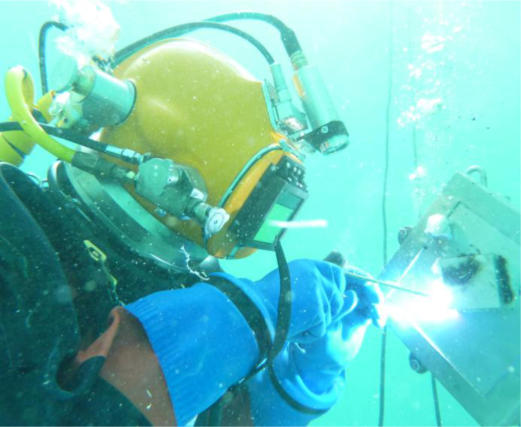

Underwater welding training in a swimming pool

New Composite Beat Engel helmet model DSL B2 CN.

Note the removable weight also acting as a protector.

Diver dressing (above) and cleaning before undressing

(below). Note the protective suits of the assistants.

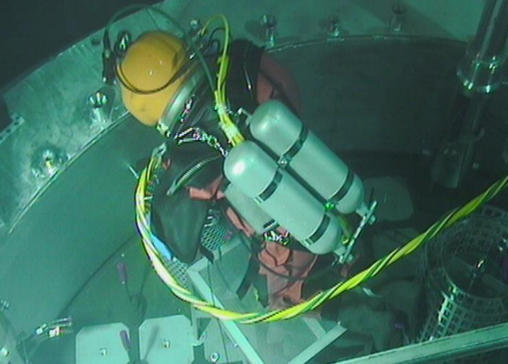

Launching the dive in a reactor pool

Intervention in a combustible pool

Click on the

octopus to return to

the top of the page