Offshore geothermal resources (June 2022)

Click on the

octopus to return to

the top of the page

Authors: Darren Atkins and Haraldur Audunsson

The world’s oceans hold abundant geothermal

resources, none of which are being utilized today. The

majority of these high-temperature resources lie along

mid-ocean ridges.

The authors describe exploration techniques that can

be used for locating hydrothermal vents, such as

towing a variety of temperature, chemical, and optical

sensors from a ship and using various underwater

vehicles. Then geophysical methods such as resistivity,

magnetic, seismic, and gravity surveys for defining

reservoir characteristics were looked at.

Authors: F B Armani, p Paltrinieri

Italy is the first European and world's fifth largest

producer of geothermal energy for power generation

accounts for less than 2% of the country's total

electricity production. In this paper, after a brief

introduction to the essential elements of high-enthalpy

geothermal systems, the authors discuss the

potentialities represented by the submarine volcanoes

of the South Tyrrhenian Sea.

Authors: Francesco Italiano, Angelo De Santis, Paolo

Favali, Mario Luigi Rainone, Sergio Rusi, and

Patrizio Signanini

Italy has a high geothermal potential for power

generation.

A new target for geothermal exploration and

exploitation in Italy is represented by the Southern

Tyrrhenian submarine volcanic district, a geologically

young basin (Upper Pliocene-Pleistocene)

characterized by tectonic extension where many

seamounts have developed. Heat-flow data from that

area show significant anomalies comparable to those

of onshore geothermal fields.

Authors: Teguh Rahat Prabowo, Fithriyani Fauziyyah,

Suryantini, Sutikno Bronto

Most of the operating geothermal fields in the world

are associated with volcanic settings, which are

known as the conventional geothermal system.

Volcanoes are created in the active tectonic zone,

such as the collision zone and MOR (mid-oceanic

ridge). The latter is the one that formed the marine

volcanoes on the sea floor. The advances of today's

technology in geothermal energy have created many

ideas regarding a new kind of geothermal system,

including the concept of developing the utilization of

marine volcanoes.

Authors: Lakshman R. T. Pedamallu, Nelson E. V.

Rodrigues, and Ramiro J J Neves.

This study aims to assess Portugal's onshore and

offshore geothermal potential adequately.

The further part of the study also addresses the

directives and legislative instruments of geothermal

energy production in Portugal.

Authors: Lakshman R. T. Pedamallu, Gerardo Hiriart,

Nelson E. V. Rodrigues, amiro J. J. Neves, and

J. V. Cruz.

Hydrothermal fluids are generally with high heat

flows and dissolved minerals, making them an

excellent target for exploitation of hydrothermal energy

and mineral resources.

The energy extraction from the hydrothermal vents

could provide a carbon-free and sustainable source of

energy for future generations.

Authors: Lakshman R. T. Pedamallu, Ramiro J. J. Neves,

Nelson E. V. Rodrigues, and J. V. Cruz.

The geothermal brines of the mid-ocean ridge

hydrothermal vents are believed to be potential

sources of offshore geothermal energy. These fluids

represent one of the most abundant energy resources

worldwide, due to their enormous quantity, infinite

recharge, and high temperatures. However, all forms

of electricity generation impact the environment in

some way. The ecological and biological importance

of the vents restricts the number of areas that can be

utilized to produce electricity.

Authors: F R Widiatmoko, D D Dewangga, A

Gustriandy, S Salsabila, N Anggraeni, M

Infithor, D Hanifah, R A Pratama, T H Kusaeri,

and A Zamroni

Sangihe Archipelago is known as the volcano arc

formed by the subduction of the Philippines plate

beneath the Micro-Sunda plate. The objective opf

these studies is to search the high-value gravity at the

high topography as an indication of the magmatic

product on the seafloor and the low value of magnetic

as an indication of the active heat resources.

Authors: Mazlan Madon & John Jong

A long overdue update of offshore Malaysia's

geothermal gradient and heat flow maps based on oil

and gas industry data. This article presents an update

based on available data and information compiled

from PETRONAS and operator archives. More than 600

new data points calculated from bottom-hole

temperature (BHT) data from oil and gas wells were

added to the compilation, along with 165 data points

from heat flow probe measurements at the seabed in

the marine areas off Sarawak and Sabah. The heat flow

probe surveys also directly measured seabed sediment

thermal conductivity.

Authors: Yonghui Huang, Yuanzhi Cheng, Lu Ren, Fei

Tian, Sheng Pan, Ke Wang, Jianwei Wang,

Yuexia Dong, and Yanlong Kong

Assessment of available geothermal resources in the

deep oilfield is essential to exploiting oil and

geothermal resources synergistically. A revised

volumetric approach is proposed in this work for

evaluating deep geothermal potential in an active

oilfield by integrating a 3D geological model into a

hydrothermal (HT)-coupled numerical model

Authors: Diego Paltrinieri, Paolo Favali, Francesco

Italiano, Patrizio Signanini, Carlo Caso, and

Fabrizio B. Armani.

This article discusses an excursus on the activities

carried out on offshore geothermal areas worldwide.

The authors focused on the energy potential capacity

of the Marsili volcanic seamount located over the

bathial plain of the Tyrrhenian Basin, describing the

detailed geological, geochemical, and geophysical

investigations carried out on that seamount since the

2000s.

Authors: Diego Paltrinieri, Paolo Favali, Francesco

Italiano, Patrizio Signanini, Carlo Caso, and

Fabrizio B. Armani.

This article discusses an excursus on the activities

carried out on offshore geothermal areas worldwide.

The authors focused on the energy potential capacity

of the Marsili volcanic seamount located over the

bathial plain of the Tyrrhenian Basin, describing the

detailed geological, geochemical, and geophysical

investigations carried out on that seamount since the

2000s.

Videos

1 - Hydrocarbon to Geothermal Well Conversion Insights -

Dr Joseph Batir (Petrolern).

This video describes the steps to convert oilfields to geothermal production fields

with the advantages and inconveniences of such a process.

Petrolern is a technology company working on subsurface solutions for carbon

storage, geothermal and oil and gas projects based in Altanta , georgia, USA.

Website: https://www.petrolern.com

2 - Geothermal energy potential in the Northsea oil and gas .

industries - Georges E. Lockett.

This video was recorded during a lecture. It is not indicated when and where it was

organized.

Contact details Georges E. Lockett:

Email: Georges.lockett39@gmail.com

Phone: 01286 882701

3 - Transforming oil wells into geothermal wells

Giona Falcone - International Geothermal

This video is the recording of the ITB International Geothermal Workshop in July

2021.

This workshop seems to have been organized by the University of Glasgow.

We are continuing the discussion on alternative markets to the oil

and gas industry that may initiate new opportunities for diving and

ROV companies with “offshore geothermal resources” for power

production.

The name “Geothermal” comes from the Greek gêo (earth) and

thermos (hot). Geothermal energy designates both the science that

studies the internal thermal phenomena of the globe and the

industrial processes that aim to exploit it. The advantage of this

energy is that it is independent of external climatic events and is

available 24/7.

The phenomena of convection and internal conduction of the globe

associated with the degradation of the natural radioactive elements

contained in the subsoil produce this heat flow. It is commonly

admitted that the temperature of the subsoil is no longer influenced

by daily climatic events (day-night changes, rain, winds, etc.) at

approximately 20 m depth, corresponds to the average temperature

(hot & cold periods) at the surface at 100 m, and increases with an

approximate average of 3°C every 100 m beyond this level. However,

this phenomenon, called "geothermal gradient", varies according to

the geological and structural context, the circulation of underground

waters, and the altitude. Thus, a rise of 10 °C every 100 m is noted

in some areas that can fall to only 2 °C in some others.

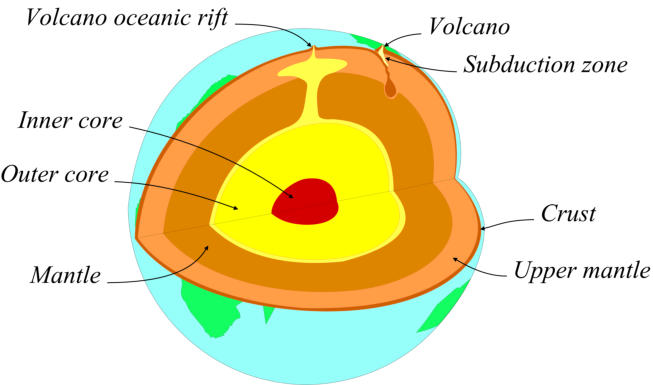

Note that the thickness of the earth's crust ranks from

approximately 30 km to 60 km, depending on the place. Also, its

temperature can be up to 1000 °C near the upper mantle. The

temperature of the mantle is estimated from 1000 (upper mantle)

to 3000 °C (Mantle near the outer core).

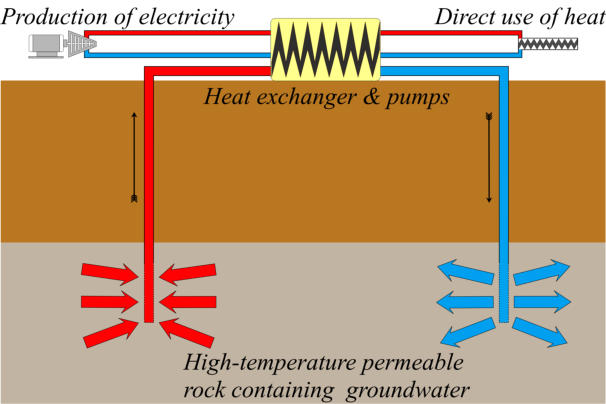

Specialists usually classify the geothermal resources as follows:

•

A “very low geothermal resource” provides a temperature below

30°C. It is the energy contained in the ground or shallow

groundwater. It can be exploited using closed exchangers to

maintain the temperature of individual houses and buildings

and produce hot water. A closed exchanger system consists of

water treated against freezing and circulated in a closed circuit

by a pump. The pipes are placed at depths varying between 2

and 100 m underneath or near the house or the building they

are planned to heat during the cold season and cool during the

hot season (see below). Such geothermal energy is, of course,

not usable offshore.

•

“low geothermal resource” corresponds to a resource whose

temperature is between 30 and 90°C. It is directly usable for

thermal applications through closed-circuit systems similar to

those above. Most of these resources are located in

sedimentary basins and employed to heat towns and individual

habitations.

•

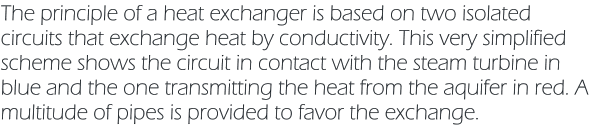

A “medium geothermal resource” corresponds to a resource

whose temperature is between 90 and 150°C. It generally uses

the hot water from aquifers and is indirectly recoverable for

electricity production by using low vaporization temperature

fluids in closed circuits and large heat exchangers, or be

directly used for the applications already described above. That

can be done by capturing water from hot water springs at the

surface or by drilling a well and installing pumps that circulate

water to and from a heat exchanger that captures the calories

from the aquifer. A second borehole returns this water to the

aquifer. Note that this water cannot be sent as it is to a heating

network because it is usually loaded with mineral salts which

crystallization would quickly clog all pipes and valves. For this

reason, this water transfers its heat to an exchanger before

being reinjected into the aquifer. This reinjection is also

necessary because the salts from these deep aquifers cannot

be released into surface ecosystems. Moreover, if the water is

pumped without reinjecting it into the groundwater, the

pressure quickly decreases, and the pumping well dries up.

The quantity of calories captured depends on the depth and the

presence of a thermal anomaly. When there is no groundwater,

another process consists of injecting water from the surface

through a borehole and recovering the heated water at the

surface to extract the calories before injecting it back to depth.

Note that pumping water cannot be done without energy, so the

power necessary for this process has to be considered.

•

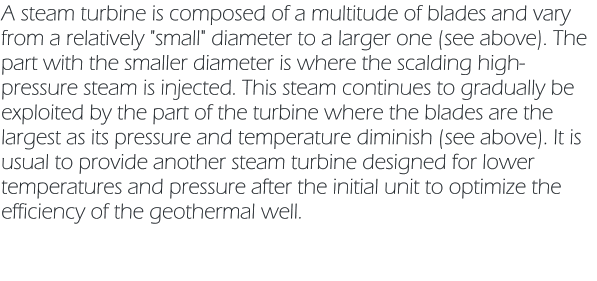

A “high geothermal resource” corresponds to a resource whose

temperature is above 150°C. It is directly exploitable for

electricity production and is generally located near large

volcanic arcs. Exchangers (see a model from Trianon below),

and steam turbines (see a model built by Alstom below) are

commonly used to exploit it.

Unlike what many people promoting this type of energy production

pretend, these installations exploit non-renewable heat. That is linked

to the fact that they gradually cool the rocks and the aquifer

between the pumping and injection wells. As a result, the heat

transfer is gradually less efficient, and the wells are considered

dead after a duration estimated between 30 and 100 years,

depending on the initial temperature and the size of the aquifer.

Also, it is estimated that the earth loses approximately three times

the power currently produced and consumed by humanity. As this

energy is continuously dissipated, many consider it inexhaustible on

a human scale. However, some specialists say that since

humankind's energy consumption doubles every 30 years, this

energy reserve might not be sufficient from approximately 2050 if

this consumption trend is continued. Nevertheless, despite the fact it

is not renewable and potentially limited, geothermal energy does not

produce waste. Thus, there is no reason not to exploit it.

It must be noted that geothermal energy remains marginally

employed, even though several production plants are in service and

despite the high potential of efficiency in many regions of the world.

Also, offshore geothermal energy has not been considered a

feasible option for many years, mainly when the oil and gas prices

were low.

Nevertheless, the continuously increasing hydrocarbon prices and

new approaches to exploiting this resource, such as electricity and

hydrogen production, make its utilization attractive. It also presents

the advantage that it can be implemented on oilfields that are no

longer productive and thus replace hydrocarbons production

without too expensive an investment. Also, the technology to exploit

this energy offshore is already there. As an example, deep drilling

processes that were problematic several decades in the past are

today well controlled, and water injection is a process commonly

used in oilfieds.

The advantage of offshore production plants compared to facilities

installed on land is the same as those of offshore wind farms.

Thus, they do not need a detailed assessment of conflicting

activities with neighbors, which is mandatory in many countries,

and no significant land space acquisition is required. That avoids

direct conflicts with most local populations and is a substantial

factor for easy exploitation. Of course, ecological evaluations of their

impact are to be undertaken. Nevertheless, it has already been said

that the environmental impact of these production units is limited

and has already been done in the case of recycled oilfields. Some

conflicts may arise with fishermen if the fields are too close to their

fishing areas. That has already happened with wind farms and tide

turbines, even though the absence of hydrocarbons should have

made such production plants more admitted and have contributed

to considering them underwater life reserves. Regarding this point,

it must be noted that recycled oilfields would provide an additional

advantage as their exclusion zones are already delimited. Also, as

said in our discussion on wind farms, far offshore sites offer the

advantage that they are less visited by anglers and thus, are more

admitted by this category of people whose interests often conflict

with those arising from such production plants.

Like almost all sustainable energy systems available on the market,

the economic side is the main problem regarding the feasibility of

these production units. As said above, this disadvantage diminishes

as the prices of hydrocarbons rise, and recent conflicts show that

energy independence is crucial for developing countries. Also, these

costs are said to be widely cut for projects that consist of recycling

oilfields at the end of life.

Multiple configurations are considered by specialists. Their final

selection will depend on their feasibility and their productivity. Note

that it is evident that a significant challenge is to keep the water

extracted as hot as possible to obtain maximum efficiency.

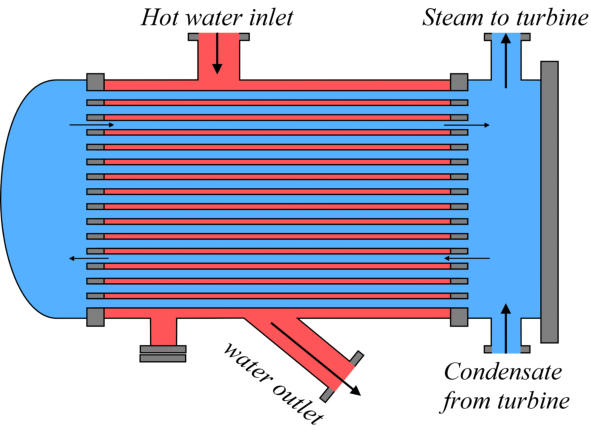

Among the solutions commonly discussed, the one that consists of

using jackets or other offshore facilities to install equipment that

transforms the energy from the hot water into electricity above the

surface of the sea on the extraction site is often considered (see

below). In this case, the scalding water is pumped from the seabed

to the facility and reinjected after usage, as described previously.

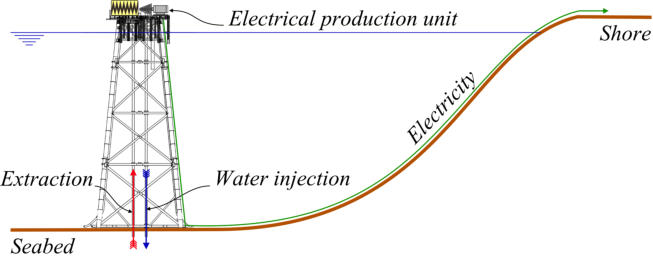

Another suggested solution is to install multiple production units on

the sea floor and manage them from a facility that can be a

platform or a floating facility from which the electricity is directed to

the shore or used to produce hydrogen that is then stored in an

FSO (Floating Storage and Offloading) anchored on the field. For the

production unit’s owner, the advantage of such a configuration is

that the heat loss is minimized, and the disadvantage is that more

underwater interventions will be necessary to maintain the

systems, which is, in fact, an advantage for diving and ROV teams.

A lot of variations of these two configurations can be imagined.

However, we can see that they do not differ from those commonly

found in oilfields where several wellheads are controlled from a

central facility, and the oil is exported through tankers and pipelines

Based on the above, we can note that oil and gas companies are

among the most competent for implementing such projects because

they already have the technology for that. Nevertheless, nothing

should stop a government or private investors from launching such

a project that may consits of reemploying an abandoned petroleum

concession that has been confirmed suitable for this purpose or

building a specific exploitation field.

The main advantage of these projects for diving and ROV

companies used to work for oil & gas companies is that they are

performed in environments they are familiar with, and based on

operating procedures already in force in the oil and gas industry. In

addition, harms linked to the risks of flammability and explosion of

the substances extracted are eliminated. Thus working near such

production units should be safer and more comfortable.

However, we spent a lot of time on the internet to find an offshore

geothermal plant in service, and unfortunately, we did not find any. A

few geothermal plants are currently under construction, but they

are all inland except one near the shore on the west coast of the

USA. In conclusion, despite its numerous theoretical advantages, we

cannot say that the offshore geothermal industry has started, even

though there are currently many discussions, technical studies, and

environmental investigations promoting them. Thus, according to

what we can see, they have not yet resulted in the actual

implementation of a project.

Of course, if someone knows about such a project, we will be happy

to relay some documented information in the next update of the

website.

As for the previous topics of this cycle of discussions about potential

economic opportunities for the diving & ROV industry development,

papers and website addresses are provided to allow the reader to

make his own opinion. They are accessible through the links below.