About nitrox fabrication (August 2022)

The development of the substitute energies to hydrocarbons

described in the previous food for thought topics has resulted in

many dives being performed at shallow depths where “nitrox” can

replace air to increase productivity and safety. For example, using

the COMEX table MT 92 and a mix of 40% oxygen, the equivalent

depth allows a no-decompression dive of 165 minutes at 18 m

instead of 50 minutes with air.

However, numerous companies do not apply these procedures

despite their advantage. One of the reasons is linked to the fact that

they are more complex to implement than air diving, and another

one is the price of oxygen.

The complexity of the implementation of nitrox is often linked to

personnel formation and is not discussed in this article. However,

difficulties related to the price of the oxygen can be partially solved

by fabricating nitrox mixes using specific membrane systems or

fabricating oxygen that can be used to compose nitrox by using

oxygen generators. Manufacturers say these devices can save up to

50% of the price of oxygen classically manufactured by cryogenic

separation.

Let’s start describing these machines with the fabrication of nitrox

using membrane systems:

1 - Description

Membrane systems selectively separate nitrogen and oxygen, from

the air. They have the advantages of fabricating nitrox at a low cost,

reducing logistical problems, and being easily transportable. They

can be classified into two main categories, which are not based on

the same principle of work.

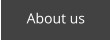

“Hollow fiber membranes” consist of hollow tubes made of fiber

manufactured by a co-extrusion-like process. The permeance of

gasses across the polymeric membrane is based on the solubility of

the gas in the polymer and the rate of gas diffusion across the

membrane. For these reasons, polymers are selected for the

membranes that are conducive to high permeance efficiency, light-

weight, and reliability.

The cross-section of a typical fiber has an outside diameter of 140-

180 microns and an inside diameter of approximately 100 to 140

microns. The majority of the fiber wall thickness is a porous

sponge-like material that makes up the fiber core. The purpose of

the core is merely to support an outer boundary layer of a thickness

of approximately 2 microns, called the sheath, where gas separation

occurs. The sheath and the outer skin of this layer, measured in

angstroms, determine the performance of the membrane.

These fibers are assembled in bundles to form the air separation

modules. The air is supplied at one end of each fiber and moves to

the other end. During this process, oxygen is absorbed through the

polymer walls of the fiber due to the pressure difference. As a

result, the gas that exits the downstream end of the hollow fiber is

decreased in oxygen concentration. Therefore, oxygen-enriched air

with oxygen concentration up to 40% is produced .

The advantages of this technology include the absence of moving

parts, the low weight, the inexpensive nature of the materials of

construction, and the lack of any substantial time lag in system

start-up.

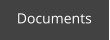

The air inlet pressure is usually between 13 & 14 bar. This inlet air

should be filtered and dried to limit the particles size to 0.01µm, and

having a maximum oil vapour content below 0.01 mg/m³.

Several companies produce modules that are designed to be

compiled with adequate filtration systems and compressors. It is,

for example, the case of Parker, L’Air Liquide, Gereron, and others.

The scheme below shows how a nitrox production unit using these

modules should be organized.

Note that the NASA study “Onboard oxygen generation system” says

that that multi staging can improve the concentration of the oxygen

provided by such membrane systems.

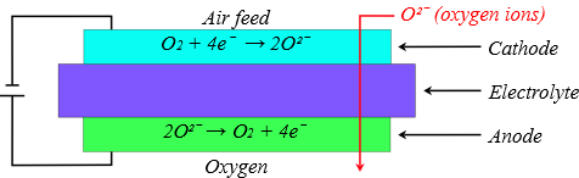

The second category of membrane separation systems is called

“ceramic membranes”. The principle of the ceramic oxygen

permeation process uses the catalytic properties of specialized

ceramic materials to transfer the oxygen in the form of ions instead

of molecules, so the ions of other gas molecules cannot pass

through the membrane. As a result, the oxygen concentration can

reach 99.5% or even higher. The system is based on a membrane

where one side is the cathode, and the other is the anode that is

separated from the cathode by an electrolyte. Oxygen molecules'

absorption starts at the membrane's cathode side, where they are

dissociated into oxygen ions. These oxygen ions migrate to the anode

side through the membrane and then recombine into oxygen

molecules. The compensation of electric charges during the process

is achieved through reverse-direction migration of the electrons in

an external electric circuit. Note that the operating temperature of

ceramic membranes is between 600 and 900 °C.

Like hollow fiber membranes, ceramic membrane systems do not

use moving parts. In addition, they have the advantage of not being

sensitive to water vapour and other contaminants. Nevertheless,

these devices need to be energized by an electric circuit to work.

These systems are fabricated mostly for aerospace and defense

industries.

2 - Design and operating procedures of a system

Like for other types of equipment, it is essential to study an existing

system's design and operating procedures to understand better

how such equipment can be adapted to commercial diving activities.

The device taken as a reference is the "230n3 Series" created by

"Nuvair" (https://www.nuvair.com/), a company based in Oxnard,

California, USA. This system, which is among the most sold, can

supply nitrox with an oxygen concentration of up to 40%.

1.

The Membrane Systems require a source of clean,

pressurized, and heated air for separation. The two most

common sources are a Low Pressure Compressor (LP Supply)

or High Pressure air storage tanks (HP Supply).

2.

The air must be properly filtered to be “oxygen compatible”

quality prior to entering the membrane system so it will not

damage or plug the membrane fibbers. Standard systems are

rated for maximum supply pressures of 17 bar (250 psi) for

LP Supply and 345 bar (5000 psi) or sometimes more for HP

Supply.

3.

An “input pressure regulator” reduces these pressures to

acceptable levels for the membrane.

4.

The air is then heated to a temperature that provides stability

over a wide range of ambient conditions and is optimal for

membrane permeation.

5.

The heated air enters the membrane, which is made up of

thousands of miniature hollow fibers. The walls of these fibers

are semi-permeable and designed for different gases to move

through them (or permeate) at different speeds. The resulting

gas mixture is known as the “permeate”.

6.

As air flows through the hollow fibers, both oxygen and

nitrogen permeate through the fiber walls. The oxygen

permeates faster than the nitrogen, which produces permeate

with an oxygen content greater than air. The gas that reaches

the end of the hollow fibers without permeating is almost

entirely nitrogen and is discharged. The flow rate of this

discharge is set by the factory via a fixed orifice to allow the

membrane to operate at maximum volume and efficiency. The

resulting permeate contains approximately 40% O2 and is

constant under all operating conditions.

7.

The permeate is a concentrated mixture that must be diluted

with additional air prior to entering the nitrox compressor. It

exits the membrane at ambient to slightly negative pressure

and travels into the “mixing tube”, where it mixes

homogeneously with filtered outside air. The amount of dilution,

and thus final % O2 , is obtained by adjusting the “input

pressure regulator”: As pressure is increased, permeate flow

increases, air flow decreases, and a higher % O2 Nitrox is

produced. As pressure is decreased, permeate flow

decreases, air flow increases, and a lower % O2 Nitrox is

produced. This relationship between permeate flow and air

flow exists because the total of these two flow rates will always

equal the intake flow rate demanded by the Nitrox Compressor.

8.

The resulting nitrox mixture is analysed for approximate % O2

before entering the nitrox compressor and again prior to use

for precise % O2 .

9.

The input pressure that correlates to a specific nitrox % O2 is

repeatable. If nitrox with 36% O2 is produced when the input

pressure is at 9 bar (125 psi), then adjusting the Regulator to

the same pressure during the next use will produce the same

gas mixture.

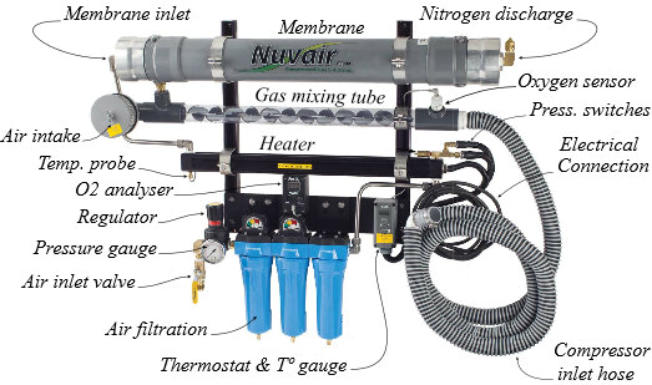

Identification of the components of a system supplied with low

pressure:

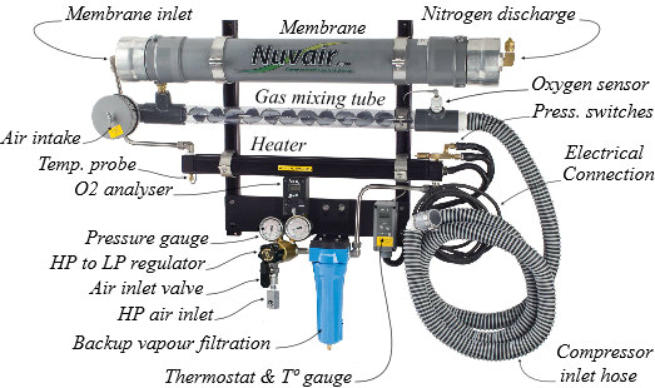

Identification of the components of a system supplied with high

pressure:

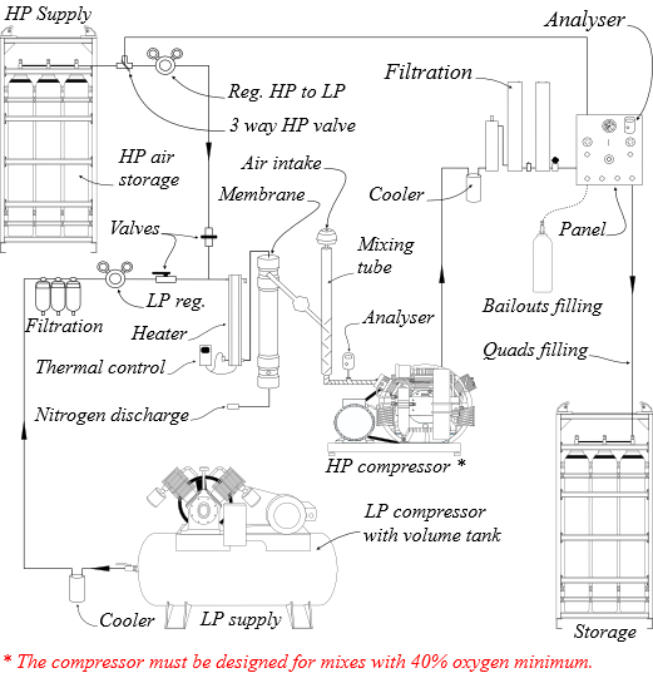

Overall view of the components of a system supplied with high and

low pressure:

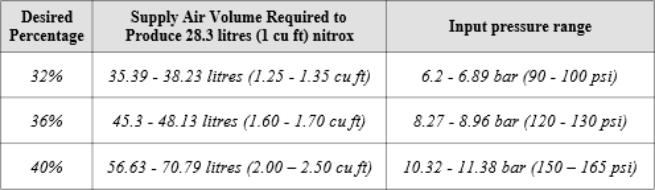

As said previously, the higher the % of O2 desired in the final

product, the greater the volume of supply air, and the higher the

input pressure required, as shown in the example below for a 10

cfm (283 L/min) membrane system:

The air supplied should comply with EN 12021 or CGA G-7.1-1997

grade D or E.

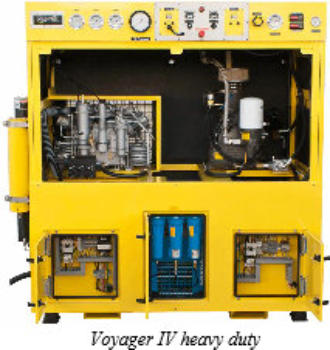

Manufacturers of nitrox membrane systems also sell complete

ensembles that include the compressor, such as the machine below

designed by Nuvair that can produce up to 481 litres/min of nitrox

40 % (max. pressure: 250 bar).

3 - Where to install the machine?

Like all air compressors used on worksites, the machine's air intake

should be placed at height and away from any potential sources of

dangerous gas. In addition, the area where it is installed should be

cleared of pollutants that may ignite oxygen such as oil and grease.

Thus, a risk assessment regarding its surrounding should be done.

Also, nitrox mixtures used for diving usually have proportions of

oxygen above 25%, so they must be handled as pure oxygen. The

document IMCA D 022 chapter 9/point 9.6 recommends not to

pump oxygen. For this reason, many companies transfer pure

oxygen and nitrox mixes by decanting only during operations at sea,

and some others buy mixes fabricated in factories.

However, a lot of companies have ceased to apply this guideline and

argue that, if relevant precautions are implemented, it is no riskier to

pump nitrox mixes offshore than implementing other operations that

are commonly done, such as fuel bunkering or the gas containers

transfer by crane. We must admit that accidents with these

machines are rare, as we have not found a recent paper regarding

such events.

For this reason, we can consider that pumping nitrox mixes is

possible if a risk assessment has been undertaken to ensure the

desirability of doing it, that the fire surveillance and fire fighting

systems are sufficient, and that this operation is performed in an

isolated ventilated part of the deck where a fire can be easily and

quickly contained. In addition to extinguishers and fire lances in

immediate proximity to the room, the fire fighting systems should

include a deluge or a water mist system with a fire alarm system

linked to the vessel's bridge,

Of course, the vessel owner, the client, and the state representative

can reject such a procedure.

Thanks to Erick Estrada & Ron Case from NUVAIRr for their

kindness and efficient support.

Purpose and potential applications:

Membrane gas separation systems used to extract the oxygen, such

as the nitrox membrane system Nuvair described in the previous

post (see in discussion “August 2022”) or models from other

manufacturers, provide nitrox mixes limited to approximately 40%

oxygen. However, it is possible to obtain nearly pure oxygen with

technologies such as Pressure Swing Absorption (PSA) oxygen

generators. In recent decades, this technology has improved to

become efficient, reliable, transportable, and financially accessible.

Like the nitrox membrane system described in the previous section,

these apparatus extract oxygen from the natural air. The purity

obtained ranks from 90 to 99.5%, depending on the equipment. Note

that 90% is the minimum required by standardization organizations.

Pressure Swing Adsorption oxygen generators are primarily used

for medical support, particularly for mobile hospitals and those

installed in isolated areas. They are also increasingly installed to

reduce the cost of therapeutic gasses in hospitals established in

towns and provide oxygen treatment for individuals at home.

However, the study of their working process proves that they can

be employed for other applications, such as the production of nitrox

mixes.

For remembering, 99.5% is the minimum recommended oxygen

purity of the European standard EN 12021, US Navy, and others. For

this reason, oxygen not complying with this minimum must not be

used for decompression and therapeutic treatments, as the tables

have been calculated according to this minimum oxygen purity. Thus,

except if the oxygen produced conforms with the above, these

apparatus cannot be used to supply pure oxygen.

However, nothing prevents us from using oxygen extracted from the

air with less than 99.5% purity for nitrox mixes, considering that the

remaining 10 to 1% of impurities of the oxygen produced by these

apparatus are nitrogen and argon.

As a result, oxygen with more than 99.5% purity can be kept for

decompression and medical treatment, and nitrox can be produced

with oxygen extracted from the air without affecting these reserves.

Note that most machines currently available on the market produce

oxygen with a purity between 93 & 97%. However, a few

manufacturers are able to sell machines producing oxygen with a

minimum purity of 99.5%.

Description:

Molecular sieves used with “Pressure Swing Adsorption (PSA)”

systems are crystalline synthetic or naturally occurring zeolites

(aluminosilicate minerals with microporous structure) with pores of

precise and uniform size that have the capacity to absorb and

separate gasses and liquids. The absorption and separation of the

molecules are based on the size of the molecules, so only small

enough ones can enter the pores, and it is also based on their

electric charge (electro-static fields). Molecular sieves are classified

according to their chemical formula and pore sizes. They are used

for applications such as drying gases, absorbing undesirable

gasses such as ammonia, methanol, ethanol, carbon dioxide,

hydrogen sulfide, and fabricating gasses such as oxygen, nitrogen,

or hydrogen.

Molecular sieves type 13X are commonly used to separate nitrogen

from the air to produce oxygen. They are the sodium form of the

aluminosilicate molecular sieves with pore diameters of

approximately 10 angstroms, an external diameter between 0.4 to

2.5 mm, and a light grey colour. They can be thermally regenerated

at temperatures from 180 °C to 300 °C. Another regeneration

method consists of gradually reducing the applied pressure.

Zeolites of Pressure Swing Adsorption systems have the

inconvenience of increasing the proportion of argon in the oxygen

delivered. As an example, for a system delivering a mix with 93%

oxygen purity, the ratio of argon is 4% instead of 1% in the

atmosphere. For this reason, NASA studies on onboard oxygen

generation systems recommend using a 2nd bed made of carbon

to absorb the excess argon.

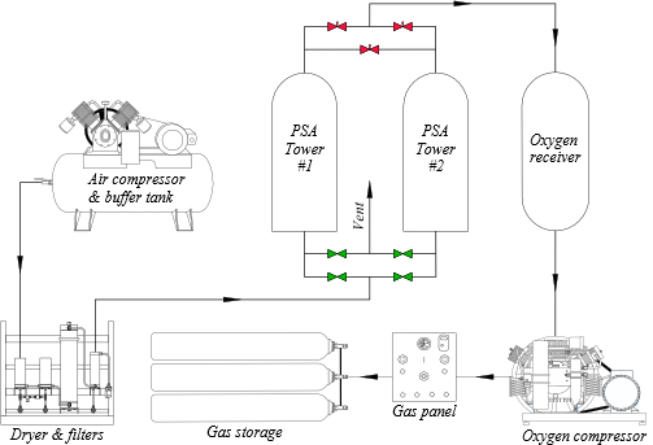

Most systems use two zeolites towers so that one unit is in use

when the molecular sieves in the second unit are regenerated. The

basic scheme of the systems commonly used is similar to the one

displayed below.

Note that the air from the compressor should be oxygen compatible.

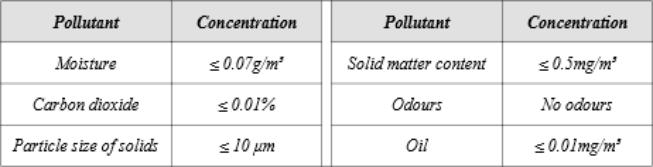

The following specifications are commonly asked:

Oil free screw air compressors are known to deliver high flow of

low pressure air, and are often preferred to supply the installations.

Also, most installations are provided with a low pressure storage

tank.

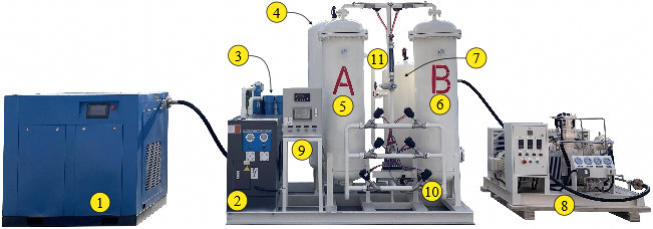

As an example of machine that can be adapted for the production of

nitrox, the Pressure Swing Adsorption (PSA) Oxygen generator

model NZO-30 PSA below, designed by Hanghou Nuzhuo Technology

co, Ltd (https://www.hznuzhuo.com/), can deliver 30 m3/hr of

oxygen with 95% purity, so 3 cylinders 50 litres/200 bar/hour. It is

made of the following components:

1 - Screw compressor 7.5 m3/min

2 - Air purification: Dryer 6

m3/min

3- Air purification: Filtration

4 - Air buffer tank

5 - Absorption tower “A”

6 - Absorption tower “B”

7 - Oxygen buffer tank

8 - Oxygen compressor 30 m3/h

9 - Controller

10 - Valves

11 - Flow meter

12 - Manifold for filling

This equipment was initially designed to be installed in ventilated

rooms with a surface of at least 30 m² and a height not less than

4 m.

However, Hanghou Nuzhuo Technology provides the photo above that

shows that this machine can be installed in a 20 feet container,

provided that adequate ventilation and fire fighting systems are in

place.

The manufacturer recommends to keep the machine at an ambient

temperature of not less than 5 ºC and not more than 49 ºC. Low

noise fans directing the hot air to the outside of the room are

suggested for this purpose and to avoid the accumulation of oxygen

in the room. Note that the heat and gas accumulation problems that

may arise due to lack of space in offshore containers can be

efficiently compensated by providing large top and bottom openings,

ensuring adequate air circulation. Usually, such openings are

provided with louvers so they can be kept open when it rains.

Waterproof external shutters are typically provided to close these

openings when the machine is not used and transferred to another

place.

Note that the controller allows managing the oxygen production and

sieve regeneration automatically.

This machine is the less powerful of the range sold by the

manufacturer taken in reference. It allows providing the necessary

oxygen (95% purity) for 24 hours diving operation at 18 m using a

mix 50/50 and 1 diver in the water within less than two hours of

compression. However, many diving operations do not need so

powerful machines, and the space available on the surface support

may not be sufficient to accommodate a container like the one

above.

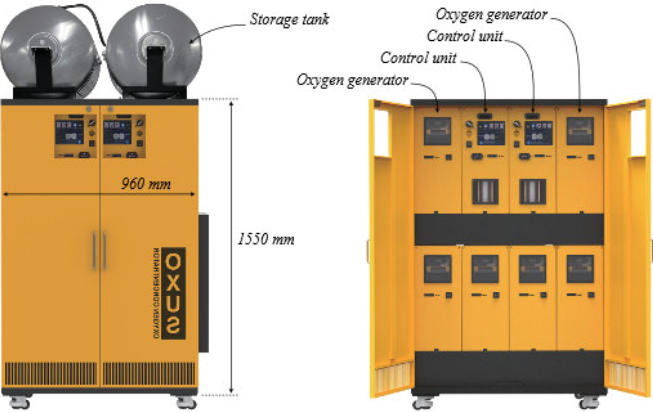

Some manufacturers specialize in less powerful and more

transportable machines initially designed for small hospitals and

individuals. It is the case of the models developed by OXUS

(https://www.oxus.co.kr/en/), a company based in Korea that sells

a range of machines installed in cabinets mounted on castors.

These cabinets accommodate several small appliances that can be

switched on and off, depending on the volume of oxygen to

fabricate. For example, the model RAK-U06M2E below is composed

of an ensemble of six small oxygen generators, each of which can

work independently and two control units.

The size of the cabinet (W x D x H) taken in reference is 960 x 600

x 1,550 mm. Optional oxygen storage tanks are provided on the top

of the cabinet. However, the system is designed to supply hospital

circuits at the outlet pressure delivered (4 - 5 bar), and an HP

compressor is to be added to the machine to fill HP gas cylinders.

OXUS provides a high pressure booster that can compress the

cylinders to a maximum pressure of 150 bar for this purpose.

This system can fabricate 3600 l of oxygen per hour, so 89400 l

per day.

Note that smaller units are also available on the market. For

example, the manufacturer of the model described above sells a

machine designed to provide 43200 litres per 24 hours and

another tiny unit designed for 7200 litres per day. Even though this

last machine is unsuitable for the fabrication of oxygen for the

diving team, it can be used in the onboard hospital for oxygen

supports other than hyperbaric treatments.

Implement the machine:

Using such machines on worksites is a new idea. However,

considering that they are successfully used for hospitals in isolated

areas, there is no reason for not implementing them, provided that

the precautions indicated by the manufacturers and above are

implemented. These precautions include the position of the air inlet

of the compressor and the elements already discussed for the

implementation of membrane systems for nitrox fabrication.

Thus, a risk assessment should be done to ensure that the

machine's surroundings are safe, and that relevant firefighting

systems are ready for use.

Of course, the vessel owner, the client, and the state representative

can reject using such a machine onboard the ship.

In addition, using the oxygen produced by such a machine to

fabricate various nitrox implies that the personnel implementing it

and then performing mixing of the oxygen with air to make the

desired nitrox must have a relevant formation.

Click on the

octopus to return to

the top of the page