About diver's bailout system design

As with many diving procedures and systems, the diver's

emergency gas supply design is a very old debate that started at the

same time it was decided to provide bailout bottles and when the 1st

models of full face masks and helmets equipped with a side supply

block appeared on the market (see below).

These debates should not exist, as there is, in fact, no reason for

that if the principles of risk assessment are correctly used.

Thus, for every problem, we have solutions, some of which are more

suitable in a given situation and less in another. To identify the most

appropriate procedure and equipment, we need to:

•

Not thinking according to dogmas.

•

Not reacting when we are under emotion (emotion is often after

an undesirable event).

•

Use history and reporting of events to clarify the problem

discussed.

•

Provide advice or take a decision only when we are adequately

documented.

•

Banish propaganda and associated fallacies.

•

keep a distance from problems to analyze them with a clear

mind.

Even though helmets equipped with a side supply block are today the

norm adopted by most manufacturers (compliance to EN 15333

standards), a few models still in service are not provided with such

a system. In this case, the side block can be replaced by a manifold

block attached to the bailout's harness. Nevertheless, it may happen

that the manifold block is not provided. In this case, the bailout bottle

is inverted (valve and regulator at the bottom side), so the diver can

easily access the cylinder's valve to open and close it. This type of

arrangement was recommended by many helmet manufacturers,

such as in the technical manual of the Aqua Lung Gorki G2000 SS

(see the image below from this manual).

Note: The Aqua Lung Gorki G2000 SS is replaced with the G3000 SS.

Some people argue that the 1st stage regulator of a bailout closed on

the bottle with no valve provided on the hat can be invaded by water

and damaged. It is not false if the helmet is flooded. However, this

problem can be easily solved by installing a non-return valve similar

to the one used for the surface gas inlet.

Another reason for closing the bailout bottle is linked to the fact that

divers involved in civil works are often working in areas where there

is absolutely no visibility, even using a light (so they are totally in the

black), and where many sharp objects that can wound them and

damage their equipment are present. For example, my first

commercial dive was performed under such conditions to install a

cofferdam in an enclosed canalization, and I was impaled on a

sharpened concrete bar no one was informed of.

In such working conditions, it is impossible to read a gauge, so the

diver does not know whether his bailout is still filled or is empty due

to a micro link he cannot detect. This is why people involved in such

missions often prefer closing the bottle's valve that must be opened

to activate the bailout. As a result, the cylinder must also be inversed

to allow easy access to the bottle's valve.

The method commonly used with helmets equipped with a side block

and further explained next is to close the two valves. Some say that

in this case, activating the bailout requires two manoeuvers.

Nevertheless, we can consider that some bailout rebreathers used in

saturation, such as the DIVEX MK4, also need two maneuvers to be

activated, which can be very quickly done.

Another reason for inversing the bottle is that when operating in

such an enclosed space, there is also a risk of damaging the

regulator and hoses due to repeated shocks with unseen objects

above the diver and sometimes the ceiling. As an example. the photo

below shows a continuous flow helmet designed for operations in

such conditions by “Composite Beat Engel” ( https://composite-

be.com/ ). In addition to the inversed gas cylinders, note the

particular arrangement of the valve handles to prevent them from

being caught and damaged by obstacles, and also the removable

protector. This design allows activating the bailout from a suitably

protected side block.

Note that firefighters arrange their breathing apparatus in the same

manner for similar reasons.

Based on the above, we can compare a few arrangements’

advantages and inconveniences and use these elements for a risk

assessment:

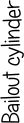

1.

Bailout bottle with the valve at the upper position and connected

to a helmet with a side block:

It is the most adopted solution and my preferred when it can be

implemented. The bottle's valve is open, and the valve of the

helmet is closed.

Advantages:

The valve is immediately and easily accessible (easy to find

and operate).

Only one hose (from the regulator to the block) which is

limiting the risk of leaks

The standby diver can wear the bailout while sitting on his

chair without the risk of damaging the regulator and

connections.

The supply hoses are those of classical SCUBA regulators

(easy to find)

Easily accessible for inspection during the check list (the lead

diver does not need to bend).

Inconveniences:

More vulnerable in enclosed spaces and areas where sharp

objects, cables, ropes, etc., are present above the diver.

A solution applied by some teams to protect the regulator is to

add a protection frame. However that has often the

inconvenience to limit the access to the valve and the

regulator.

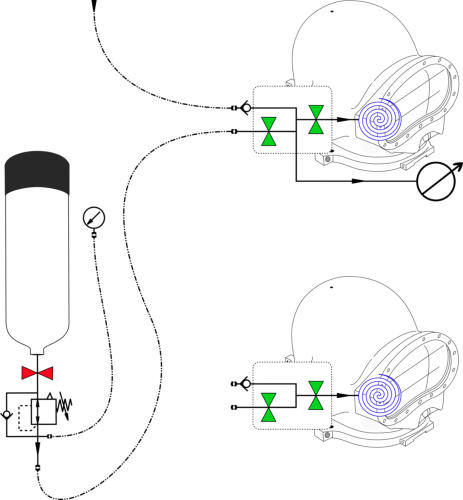

2.

Bailout bottle with the valve at the lower position and connected

to a helmet with a side block:

This solution can be used by those who need to operate in

enclosed spaces and areas where sharp objects, cables, ropes,

etc., are present. The bottle's valve is open, and the valve of the

helmet is closed. Thus, no change except that the bottle is

inverted.

Advantages:

The valve is immediately and easily accessible (easy to find

and operate).

Only one hose (from the regulator to the block) which is

limiting the risk of leaks

The bottle’s valve and the regulator are not exposed to

repeated shocks with unseen objects above the diver and

sometimes the ceiling.

Inconveniences:

The long hose must be secured (usually along the backpack),

and the technician must ensure that there are no excess

lengths.

There is a risk of damaging the regulator and connections

while the standby diver is sitting on his chair (Remember that

the standby diver must be ready to go, so dressed), which

obliges fabricating a specific chair. Still, even with such

arrangements, it happens that the regulator has shocks

resulting from lousy handling.

The regulator and the valve are protected from repeated

shocks with unseen objects above the diver, but not from

repeated contacts with objects at their level.

Less easily accessible for inspection during the checklist than

a valve at the upper position (the lead diver needs to bend).

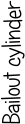

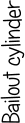

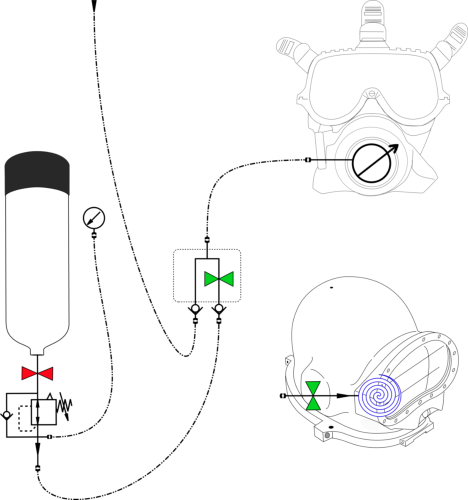

3.

Bailout bottle with the valve at the lower position and connected

to a separate manifold installed on the diver’s harness:

This system is implemented with helmets not provided with a

bailout valve, such as the Aqua Lung G2000SS, taken as a

reference for the scheme above. The bottle's valve is usually

open, and the valve of the manifold is closed.

Note that the other possibility to connect a bailout with these

types of helmets is a direct connection from the bottle (See in

point #5). Also, some old helmet models can be retrofitted with a

side block.

Advantages:

The bottle’s valve and the regulator are not exposed to

repeated shocks with unseen objects above the diver and

sometimes the ceiling.

Inconveniences:

Two hoses, so more connections (1 from the HP regulator to

the manifold & 1 from the manifold to the helmet). More

connections = more possible leaks.

The hose from the HP regulator must be secured (usually

along the backpack and the harness), and the technician

must ensure that there are not lengths in excess.

There is a risk of damaging the regulator and connections

while the standby diver is sitting on his chair (Remember that

the standby diver must be ready to go, so dressed), which

obliges fabricating a specific chair. Still, even with such

arrangements, it happens that the regulator has shocks

resulting from lousy handling.

The regulator and the valve are protected from repeated

shocks with unseen objects above the diver, but not from

repeated contacts with objects at their level.

The manifold valve is less accessible than a valve on a side

block (This is my advice based on my experience): Sometimes

the harness of the backpack moves, and the divers may not

find the manifold immediately.

The bottle’s valve and the HP regulator are less easily

accessible for inspection during the checklist than a valve at

the upper position (the lead diver needs to bend).

4.

Bailout bottle with the valve at the lower position that is closed,

and connected to a separate manifold installed on the diver's

harness or the side block of the helmet:

The bottle's valve is closed, and the valve of the manifold or the

side block of the helmet is also closed.

This method should be used only when the diver operates in a

surrounding where the equipment can be damaged, and there is

absolutely no visibility (Black), so no possibility of verifying

whether the bailout is still filled or is empty as a result of an

undetectable leak. It should not be used under normal conditions.

Also, note that closing the cylinder valve of the bailout and letting

the valve of the side block in open position to be able to activate

the bailout quicker is not a good idea: In case of a shock to the

opened valve, its stem, usually made of brass, will be easily bent,

resulting in the valve that cannot be closed, and often a leak due

to the deformation of the stem near the O-ring.

Advantages:

The bottle’s valve and the regulator are not exposed to

repeated shocks with unseen objects above the diver and

sometimes the ceiling.

Possibilities of leakages from the bottle are limited only to

those of the O-ring of the pillar valve.

Inconveniences:

In case a manifold is used: Two hoses, so more connections

(1 from the HP regulator to the manifold & 1 from the

manifold to the helmet). More connections = more possible

leaks. The hose from the HP regulator must be secured

(usually along the backpack and the harness), and the

technician must ensure that there are not lengths in excess.

In case a direct connection to a side block is used: The long

hose must be secured (usually along the backpack), and the

technician must ensure that there are no excess lengths.

There is a risk of damaging the regulator and connections

while the standby diver is sitting on his chair (Remember that

the standby diver must be ready to go, so dressed), which

obliges fabricating a specific chair. Still, even with such

arrangements, it happens that the regulator has shocks

resulting from lousy handling.

The regulator and the valve are protected from repeated

contacts with unseen objects above the diver, but not from

repeated contacts with objects at their level.

When there are two valves (bottle & manifold or side block),

activating the bailout requires opening the bottle valve 1st and

then the manifold or side block valve not to flood the

regulator. Installing a non-return valve at the helmet inlet is

“recommended” to avoid this problem.

The bottle’s valve and the HP regulator are less easily

accessible for inspection during the checklist than a valve at

the upper position (the lead diver needs to bend).

Depending on the size of the cylinder and the position of the

diver, the valve of the bottle is not as easily accessed as the

valve on the side block.

When used, the manifold valve is less accessible than a valve

on a side block.

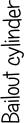

5.

Bailout bottle with the valve at the lower position and the hose

from the regulator directly connected to the helmet without

intermediate manifold or side block:

This system is provided with helmets with no side block, such as

the Aqua Lung G2000SS. The bottle's valve is closed, as there is

no intermediate valve.

The other possibility to connect a bailout with these types of

helmets is indicated in point #4. As said previously, some helmet

models can be retrofitted with a side block.

Advantages:

The bottle’s valve and the regulator are not exposed to

repeated shocks with unseen objects above the diver and

sometimes the ceiling.

Possibilities of leakages from the bottle are limited only to

those of the O-ring of the pillar valve.

Inconveniences:

The hose from the HP regulator must be secured (usually

along the backpack and the harness), and the technician

must ensure that there are not lengths in excess.

There is a risk of damaging the regulator and connections

while the standby diver is sitting on his chair (Remember that

the standby diver must be ready to go, so dressed), which

obliges fabricating a specific chair. Still, even with such

arrangements, it happens that the regulator has shocks

resulting from lousy handling.

The regulator and the valve are protected from repeated

contacts with unseen objects above the diver, but not from

repeated contacts with objects at their level.

The bottle’s valve and the HP regulator are less easily

accessible for inspection during the checklist than a valve at

the upper position (the lead diver needs to bend).

Depending on the size of the cylinder and the position of the

diver, the valve of the bottle is not as easily accessed as the

valve on the side block.

Based on the evaluations above, a hazard identification can be

undertaken that should be used for the risk assessment previously

mentioned. However, these points will be insufficient alone, and the

team should also consider:

•

The type of helmet, bailout bottles, harness, and, if used,

Buoyancy Control Device (BCD) available.

•

Whether the existing equipment can be retrofitted to a more

recent standard.

•

The configuration of the place where the operation is planned,

and whether previous ROV inspections or diving operations

have been carried out.

•

The technical level and experience of the divers.

•

Whether equipment such as a diver-held sonar system is

available for diving operations in the total black.

Of course, selecting a particular bailout arrangement for a dive or

operations in a specific area does not mean that this arrangement is

to be used everywhere, so considered the only procedure in the

company policy. For example, it is suitable to apply the first

arrangement (Bailout bottle with the valve at the upper position and

connected to a helmet with a side block) for every common operation

and select exceptionally another one for a particular operation. What

is important for organizing operations is to think of what will be the

best for the divers, and as previously said, not acting according to

dogmas, emotion, improperly reported events, propaganda, etc.

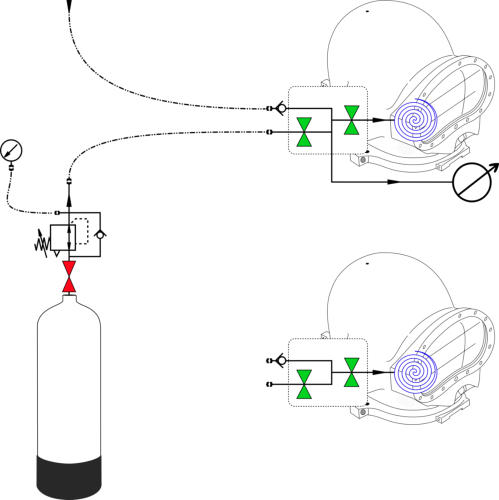

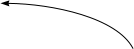

Bailout valve

Bailout inlet

Free-flow valve

Surface gas inlet

(with non retun valve)

2nd stage regulator

Regulator adjusting

The surface gas and bailout

inlets are arranged in the back

Free-flow valve

There is no bailout valve

HP to LP regulator

Flexible hose (HP or LP)

Demand valve

Pressure gauge

Free flow

Low Pressure valve

Non return valve

High Pressure valve

Legends

Continuous flow hemet

Demand valve helmet

Side block

Side block

Demand valve helmet

Side block

Continuous flow hemet

Demand valve helmet

(Gorki G2000ss type)

Manifold

Manifold

Demand valve without side block

Demand valve helmet

(Gorki G2000ss type)

Continuous flow helmet

Continuous flow without side block

Demand valve with side block

Continuous flow with side block

Click on the

octopus to return to

the top of the page